China Gold Supplier for Hard Facing Rod - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao

China Gold Supplier for Hard Facing Rod - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao Detail:

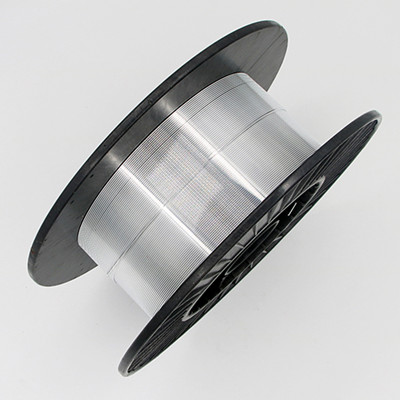

ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047

APPLICATION:

Used for jointing or overlay light alloy processing. It also widely used as filler materials in argon arc welding and oxyacetylene gas welding.

Argon arc welding is a perfect method for welding copper aluminum alloy.

Argon arc welding can not use flux, but oxyacetylene gas welding needs to use aluminum gas welding flux.

The selection of welding wire is mainly based on the type of base metal and the requirements of crack resistance, mechanical properties and corrosion resistance of the joint.

INTRODUCTION:

ER4047 is the eutectic aluminum silicon alloy welding wire with about12% Si element.

Suitable for Al-Si, Al-Si-Mg, Al Si mg Cu wrought aluminium and aluminium (7%Si) argon arc welding. Low melting point and good fluidity.

CHARACTERISTICS:

- Welding Filler Wire

- Spray and Flame Metallizing Wire

- Similar to AlSi12 (Germany), BS N21 (United Kingdom)

- Lower melting point and higher fluidity than 4043 wires

- Can be used as a substitute for 4043 wires to increase silicon in the weld metal, minimize hot cracking and produce higher fillet weld shear strength

- widely used for brazing of aluminum, Al-Mn, Al-Si-Mg alloy materials

SPECIFICATION:

MIG: 0.6mm; 0.8mm; 0.9mm; 1.0mm; 1.2mm; 1.6mm

TIG: 1.2mm; 1.6mm; 2.0mm; 2.4mm; 3.0mm; 4.0mm;

Typical Chemical Composition Of Deposited Metal:

| Cu | Si | Fe | Mn | Mg | Cr | Zn | Ti | Al | ||||||||

| 0.3 | 11.0-13.0 | 0.80 | 0.15 | 0.10 | 0.05 | 0.20 | - | Rem | ||||||||

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Our pros are lessen prices,dynamic sales team,specialised QC,sturdy factories,top quality services and products for China Gold Supplier for Hard Facing Rod - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao, The product will supply to all over the world, such as: Bahrain, Brasilia, Saudi Arabia, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!