Factory Cheap Hot Specification Of Welding Electrode - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao

Factory Cheap Hot Specification Of Welding Electrode - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao Detail:

APPLICATIONS:

It is used for cladding shafts and valves of carbon steel or alloy steel whose surfacing temperature is below 450 °C.

CHARACTERISTICS:

D507 is a surfacing electrode with low hydrogen sodium coating.

The surfacing metal is 1Cr13 semi ferrite high chromium steel.

The hardfacing layer has the characteristics of air quenching, generally does not need heat treatment,

and its hardness is uniform, and it can also be annealing-softing in the range of 750°C -800°C .

Dual purpose, good welding process. Heated to 900-1000°C, it can be re hardened after air cooling or oil quenching.

DC reverse connection is available.

WELDING POSITIONS: PA, PB

DEPOSIT COMPOSITION (QUALITY SCORE): %

| items | C | Mn | Si | P | S | Cr | Mo |

| Requirements | 0.12 | - | - | 0.024 | 0.008 | 13.47 | - |

HRC: 41

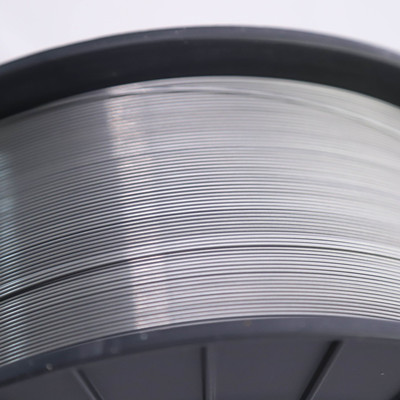

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with Factory Cheap Hot Specification Of Welding Electrode - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao, The product will supply to all over the world, such as: Dubai, United Arab Emirates, Adelaide, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you personally.

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.

Send your message to us:

Write your message here and send it to us