Factory For E316l Electrode - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao

Factory For E316l Electrode - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao Detail:

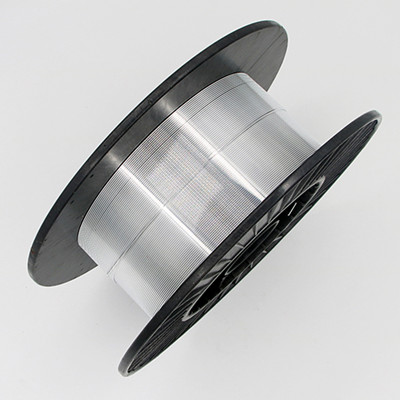

ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047

APPLICATION:

Used for jointing or overlay light alloy processing. It also widely used as filler materials in argon arc welding and oxyacetylene gas welding.

Argon arc welding is a perfect method for welding copper aluminum alloy.

Argon arc welding can not use flux, but oxyacetylene gas welding needs to use aluminum gas welding flux.

The selection of welding wire is mainly based on the type of base metal and the requirements of crack resistance, mechanical properties and corrosion resistance of the joint.

INTRODUCTION:

ER4047 is the eutectic aluminum silicon alloy welding wire with about12% Si element.

Suitable for Al-Si, Al-Si-Mg, Al Si mg Cu wrought aluminium and aluminium (7%Si) argon arc welding. Low melting point and good fluidity.

CHARACTERISTICS:

- Welding Filler Wire

- Spray and Flame Metallizing Wire

- Similar to AlSi12 (Germany), BS N21 (United Kingdom)

- Lower melting point and higher fluidity than 4043 wires

- Can be used as a substitute for 4043 wires to increase silicon in the weld metal, minimize hot cracking and produce higher fillet weld shear strength

- widely used for brazing of aluminum, Al-Mn, Al-Si-Mg alloy materials

SPECIFICATION:

MIG: 0.6mm; 0.8mm; 0.9mm; 1.0mm; 1.2mm; 1.6mm

TIG: 1.2mm; 1.6mm; 2.0mm; 2.4mm; 3.0mm; 4.0mm;

Typical Chemical Composition Of Deposited Metal:

| Cu | Si | Fe | Mn | Mg | Cr | Zn | Ti | Al | ||||||||

| 0.3 | 11.0-13.0 | 0.80 | 0.15 | 0.10 | 0.05 | 0.20 | - | Rem | ||||||||

Product detail pictures:

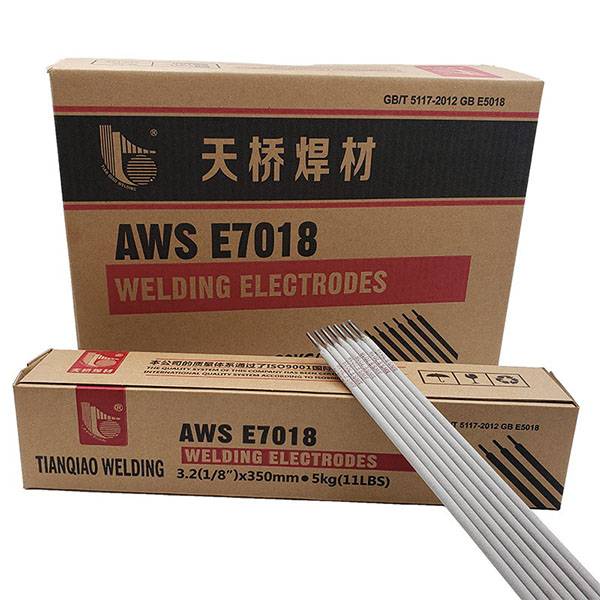

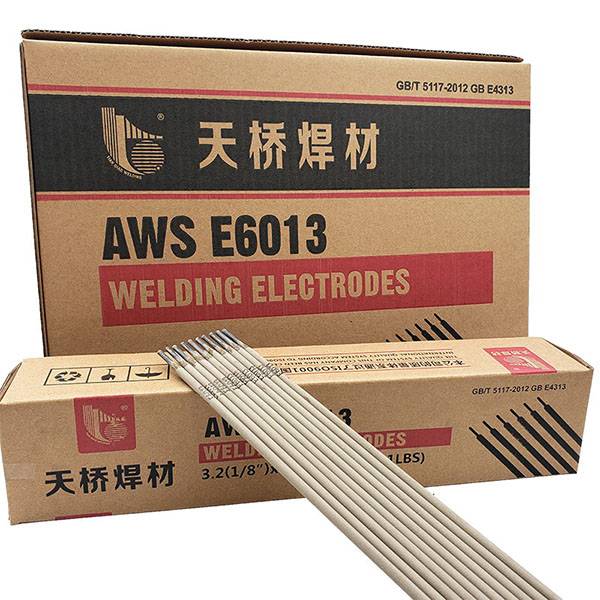

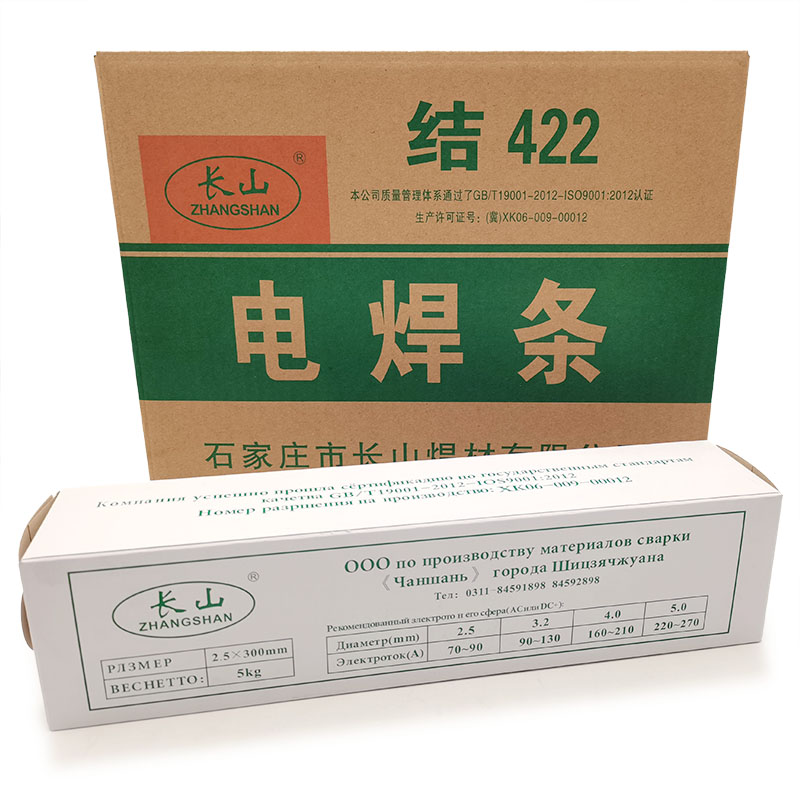

Related Product Guide:

The composition of the welding electrode

Quality comes first; service is foremost; business is cooperation is our business philosophy which is constantly observed and pursued by our company for Factory For E316l Electrode - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao, The product will supply to all over the world, such as: Georgia, Bolivia, Porto, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!