Factory For Hard Surface Welding Rod - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao

Factory For Hard Surface Welding Rod - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao Detail:

APPLICATIONS:

It is used for cladding shafts and valves of carbon steel or alloy steel whose surfacing temperature is below 450 °C.

CHARACTERISTICS:

D507 is a surfacing electrode with low hydrogen sodium coating.

The surfacing metal is 1Cr13 semi ferrite high chromium steel.

The hardfacing layer has the characteristics of air quenching, generally does not need heat treatment,

and its hardness is uniform, and it can also be annealing-softing in the range of 750°C -800°C .

Dual purpose, good welding process. Heated to 900-1000°C, it can be re hardened after air cooling or oil quenching.

DC reverse connection is available.

WELDING POSITIONS: PA, PB

DEPOSIT COMPOSITION (QUALITY SCORE): %

| items | C | Mn | Si | P | S | Cr | Mo |

| Requirements | 0.12 | - | - | 0.024 | 0.008 | 13.47 | - |

HRC: 41

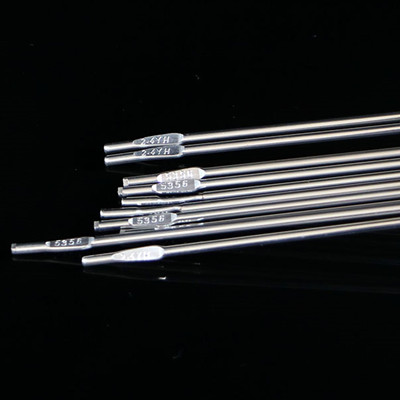

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Factory For Hard Surface Welding Rod - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao, The product will supply to all over the world, such as: Puerto Rico, Bangkok, Uganda, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services for you. We warmly welcome you to contact us and please feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

Send your message to us:

Write your message here and send it to us