factory low price Stainless Steel Welding Electrodes - E71T-GS— flux cored welding wire – Tianqiao

factory low price Stainless Steel Welding Electrodes - E71T-GS— flux cored welding wire – Tianqiao Detail:

Applications:

AWS 5.20 E71T-GS is an all-position, self-shielded flux-cored wire designed for single pass fillet and lap welding on galvanized or carbon steel as thin as 20 gauge, without burn-through. Gasless Wire E71T-GS is commonly used on small portable 110 volt welding machines, offering smooth arc action with very little spatter. Travel speed is fast, penetration is good and slag removal is easy.

NOTE: As with all self-shielded wires, E71T-GS does contain fluoride compounds, which require more attention to ventilation when being used to weld galvanized steel. The zinc oxide formed during welding should not be inhaled as it can cause metal fume fever. When welding indoors or in an enclosed area, be sure that the ventilation is adequate.

Self-shielding, all-positional flux-cored wire for single pass applications. Excellent for use on thin gauges of galvanized & mild steel. Travel speed is high & weld edges are smooth. It has a smooth arc action, full slag coverage, easy slag removal & low spatter. No shielding gas is required. The use of DC straight polarity welding current minimises the risk of burn through. Deposition efficiency is higher than that of shielded metal arc electrodes.

Shielding Gas: Gasless

Chemical Composition of deposited metal (%)

| Item | Mn | Si | P | S | A1 | Ni | Mo | Cr | C | V |

| Standard | ≤1.75 | ≤0.60 | ≤0.03 | ≤0.03 | ≤1.80 | ≤0.50 | / | / | / | / |

Mechanical Properties Of Deposited Metal

| Item | Yield Point (MPa) | TensileStrength (MPa) | Elongation (%) | Charpy V-notch Impact Toughness | ||

| Test Temp.(°C) | Impact Energy(J) | Average(J) | ||||

| Standard | ≥400 | ≥480 | ≥20 | / | / | / |

5.Size and Recommended Current (DC-) and Voltage Range

| Size | Voltage Range | Current (DC-) | Wire feed speed |

| 0.8MM | 16~18V | 100~160A | 30~60 |

| 0.9MM | 16~19V | 100~170A | 30~65 |

| 1.2MM | 16~20V | 120~200A | 35~70 |

Available Diameters:

| Dia. (mm): | 0.8 | 0.9 | 1.0 | 1.2 |

| (inch) | 0.030” | 0.035” | 0 .040” | 0.045” |

Packing :

1kg / 5kgs per spool;

precision winding, heat shrinkable film and then packed in cartons.

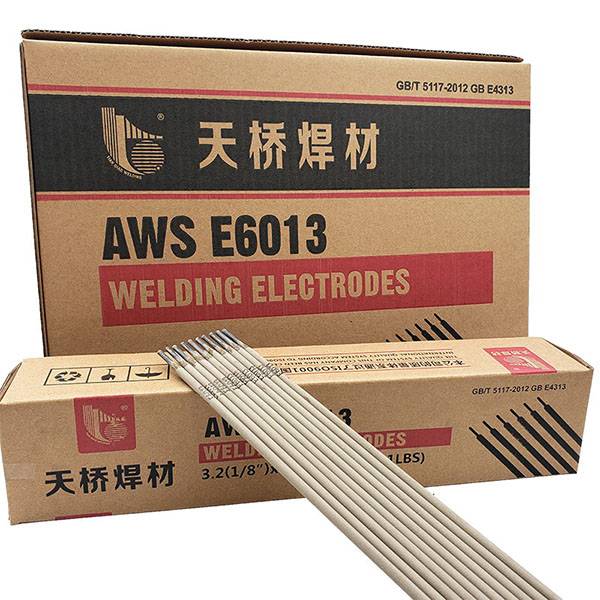

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for factory low price Stainless Steel Welding Electrodes - E71T-GS— flux cored welding wire – Tianqiao, The product will supply to all over the world, such as: Birmingham, Benin, Norwegian, Furthermore, all of our products are manufactured with advanced equipment and strict QC procedures in order to ensure high quality. If you are interested in any of our products, please don't hesitate to contact us. We will do our best to meet your needs.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!