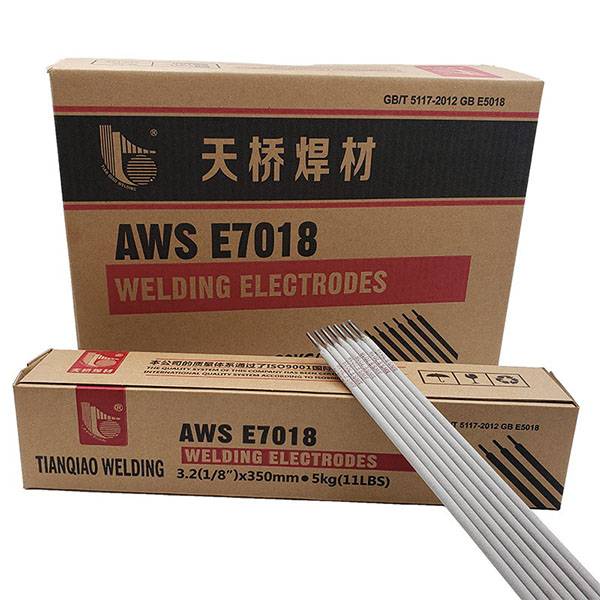

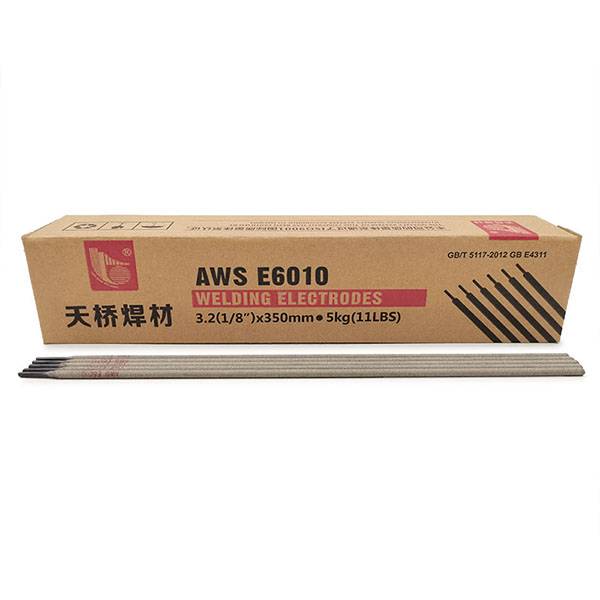

factory Outlets for Brazing Filler Rod - Mild Steel Welding Electrode AWS E6010 – Tianqiao

factory Outlets for Brazing Filler Rod - Mild Steel Welding Electrode AWS E6010 – Tianqiao Detail:

APPLICATIONS:

It is suitable for welding of low carbon steel structure as pipeline, shipbuilding and etc.

CHARACTERISTICS:

E6010 is a rutile-cellulosic sodium type electrode. Can be weld for all-position (especially for vertical-down position) with DC+ only. It have excellent welding performance as stable arc, little spatter, easy slag removal and reignition-ability etc. Better molten pool control, stronger arc force and deeper penetration at vertical-down position.

ATTENTION:

1. In generally, don’t need to re-dry the electrode before welding. When it be affected with damp, should be re-dry it at 70℃-90℃ for 1 hour.

2. The rust, oil, water and other impurities of the weld area must be removed before welding.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF, PG

X-ray flaw detection: Ⅱ level

ADVANTAGES:

Our welding electrode is of fewer spatters, less smog, stable arc, easy to restrike, less waste and etc. advantages. The most important advantage of our welding electrode is offing slag automatically.

CHEMICAL COMPOSITION OF ALL WELDS METAL: (Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requirements |

≤0.20 |

≤1.20 |

≤1.00 |

≤0.035 |

≤0.040 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typical Results |

0.09 |

0.42 |

0.15 |

0.020 |

0.025 |

0.030 |

0.035 |

0.005 |

0.004 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

Rel/Rp0.2 /MPa |

A/% |

KV2 (-30℃) /J |

|

Requirements |

≥430 |

≥330 |

≥20 |

≥27 |

|

Typical Results |

475 |

400 |

26 |

80 |

TYPICAL OPERATING PROCEDURES: ( DC+)

| Diameter (mm) |

2.5 |

3.2 |

4.0 |

5.0 |

| Length (mm) |

300 |

350 |

400 |

400 |

| Current (A) |

50-80 |

60-100 |

100-140 |

140-180 |

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging according to your design, please contact us for detail discussion.

Shijiazhuang Tianqiao Welding Materials Co., Ltd was founded in 2007. As professional welding electrode manufacturer, we have strong technical force, complete product testing equipment so that we can keep stable product quality. Our products include kinds of welding electrodes with the brand of “Yuanqiao”, “Changshan”, such as low carbon steel, Iow alIoy steel, heat-resistant steels, low temperature steel, stainless steel, cast iron, hard surfacing welding electrodes and various mixed welding powder.

The products are widely used in various national economic fields, such as machinery, metallurgy, petroleum chemical industry, boiler, pressure vessel, the ships, the buildings, s, and so on, The products are sold to all over the country, and well received by the vast users. Our products have excellent performance, stable quality, elegant welding molding, and good slag removal, good ability to resist rust, Stomata and crack, good and stable deposited metal mechanics performance. Our products are one hundred percent exported and have sold world widely, mainly to US, Europe, South America, Australia, Africa, Middle East, Southeast Asia and etc. Our products meet customers’ warm welcome due to the excellent quality, outstanding performance and competitive price.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for factory Outlets for Brazing Filler Rod - Mild Steel Welding Electrode AWS E6010 – Tianqiao, The product will supply to all over the world, such as: luzern, Toronto, Iraq, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.