Factory supplied 2.5 Mm Welding Electrode - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao

Factory supplied 2.5 Mm Welding Electrode - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao Detail:

High manganese steel surfacing electrode D256 AWS: EFeMn-A

APPLICATIONS:

It is suitable for surfacing welding of various crusher, high manganese rail, bucket, bulldozer, etc.

CHARACTERISTICS:

THD256 is the surfacing electrode of high manganese steel with low hydrogen potassium coating.Can be both ac and dc (ac welding, no-load voltage is not lower than 70V), surfacing welding should use small current, narrow welding, while the red heat immediately hammer or water quenching, in order to reduce the crack tendency.The surfacing metal is austenitic high manganese steel, which has the characteristics of working hardening, toughness and wear resistance.

ATTENTION:

1. Before welding, the electrode shall be baked at 300-350℃ for 1 hour before use.

2. For surfacing welding of worn parts of high manganese steel, the fatigue layer shall be removed or treated with water toughness or soldered with chromium manganese steel electrode (such as D277).

3. Due to the large yellow smoke during surfacing welding, attention should be paid to strengthen ventilation and operate in the windswept position.

WELDING POSITIONS: PA, PB, PC, PD, PE, PF

DEPOSIT COMPOSITION (QUALITY SCORE): %

| Items | C | Mn | Si | Others |

| Requirements | ≤1.10 | 11.00-16.00 | ≤1.30 | ≤5.00 |

TYPICAL OPERATING PROCEDURES: (AC,DC)

| Diameter (mm) | 3.2 | 4.0 | 5.0 |

| Current (A) | 70-90 | 100-140 | 150-180 |

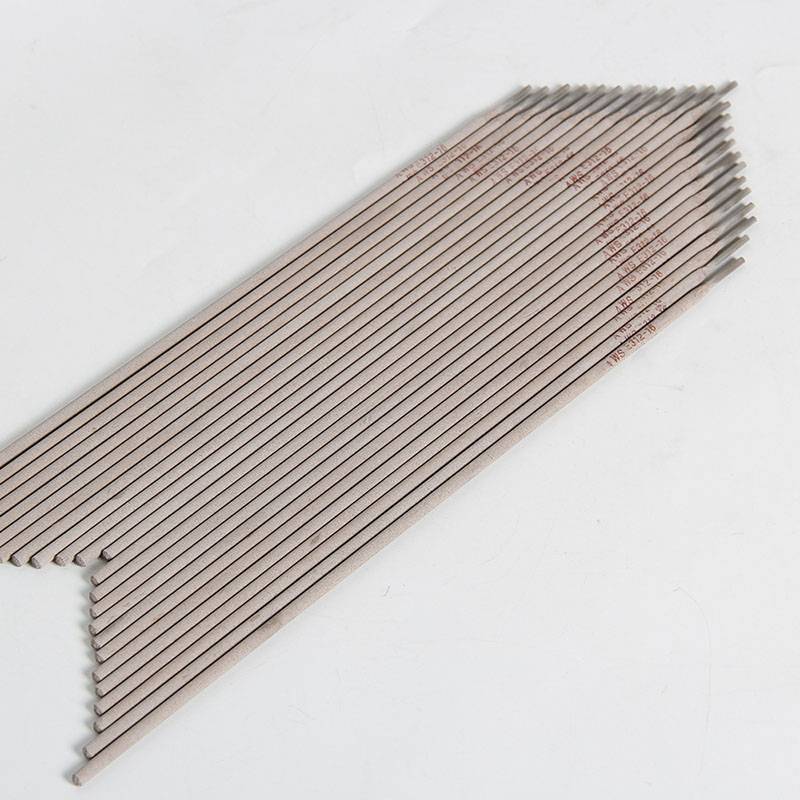

Product detail pictures:

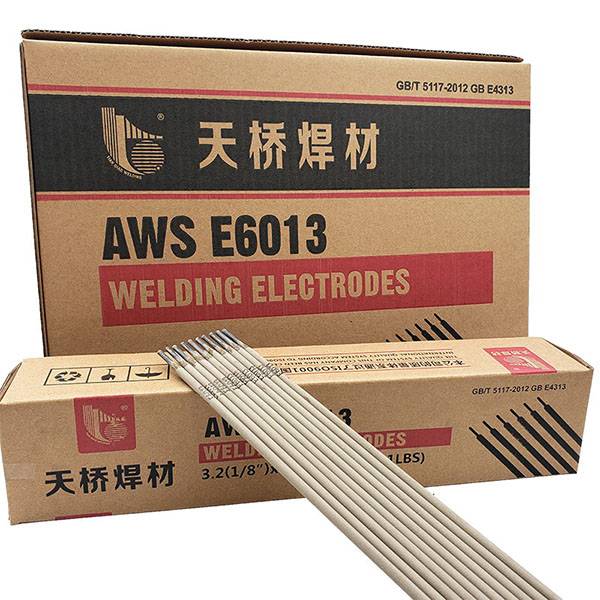

Related Product Guide:

The composition of the welding electrode

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for Factory supplied 2.5 Mm Welding Electrode - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao, The product will supply to all over the world, such as: Barcelona, Iraq, Azerbaijan, On today, we've got customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to deliver the highest quality products with best price. We've been looking forward to doing business with you!

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.