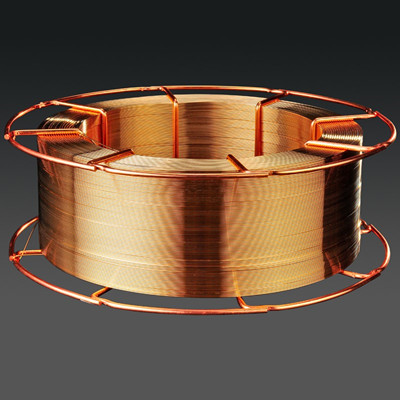

Factory Supply China Supplier Ercusn-C Welding Wire

That has a sound business enterprise credit history, excellent after-sales assistance and modern production facilities, we now have earned an superb status among our buyers across the whole world for Factory Supply China Supplier Ercusn-C Welding Wire, We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

That has a sound business enterprise credit history, excellent after-sales assistance and modern production facilities, we now have earned an superb status among our buyers across the whole world for China Ercusn-C, welding wire, With nearly 30 years’ experience in business, we’re confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Bronze alloy welding wire Silicon Bronze Welding Wire CuSi3 ERCuSi-A CuSi3Mn1 brazing rod

Silicon Bronze

|

Chemical Composition (%) |

|||||||||||||

|

Standard |

Class |

Alloy |

Cu |

Al |

Fe |

Mn |

Ni |

P |

Pb |

Si |

Sn |

Zn |

Others |

|

ISO24373 |

Cu6560 |

CuSi3Mn1 |

Bal. |

0.02 |

0.5 |

0.5-1.5 |

- |

0.05 |

0.02 |

2.8-4.0 |

0.2 |

0.4 |

0.5 |

|

GB/T9460 |

SCu6560 |

CuSi3Mn |

Bal. |

Max 0.01 |

Max 0.5 |

Max 1.5 |

- |

- |

Max 0.02 |

2.8-4.0 |

Max 1.0 |

Max 1.0 |

Max 0.5 |

|

BS EN14640 |

Cu6560 |

CuSi3Mn1 |

Bal. |

0.01 |

0.5 |

0.5-1.5 |

- |

0.02 |

0.02 |

2.8-4.0 |

0.2 |

0.2 |

0.4 |

|

AWS A5.7 |

C65600 |

ERCuSi-A |

Bal. |

0.01 |

0.5 |

1.5 |

- |

- |

0.02 |

2.8-4.0 |

1.0 |

1.0 |

0.50 |

|

DIN 1733 |

2.1461 |

SG-CuSi3 |

Bal. |

Max 0.01 |

Max 0.3 |

0.5-1.5 |

- |

Max 0.02 |

Max 0.02 |

2.8-4.0 |

Max 0.2 |

Max 0.2 |

Max 0.4 |

Physical Properties and Mechanical Properties:

|

Solids-Temperature |

910°C |

Liquids-Temperature |

1025°C |

|

|

Density |

8.5kg/dm3 |

Tensile Strength |

330-370N/mm2 |

|

|

Elongation |

40% |

Brinell Hardness |

80-90HB |

APPLICATION:

Best for butt and the hard facing of brass, especially for the MIG welding of zinc coated steel sheet.

Pre-heat suggested when MIG hard facing for large size products and the use pulsed argon arc welding while hard facing on steel.

|

MIG Welding Wires |

||||||||||

|

Diameter |

Packing |

Weight |

||||||||

|

Metric |

0.8mm |

0.9mm |

1.0mm |

1.2mm |

1.6mm |

2.0mm |

D100mm |

D200mm |

D300mm K300mm KS300mm |

1kg/5kg/12.5kg 13.6kg/15kg |

|

British |

0.030″ |

0.035″ |

0.040″ |

0.045″ |

1/16″ |

5/64″ |

||||

|

2lb/10lb/27lb 30lb/33lb |

||||||||||

|

Drum |

200kg/250kg 440lb/550lb |

|||||||||

|

Wooden Spools |

200kg-250kg |

|||||||||

|

500lb |

||||||||||

|

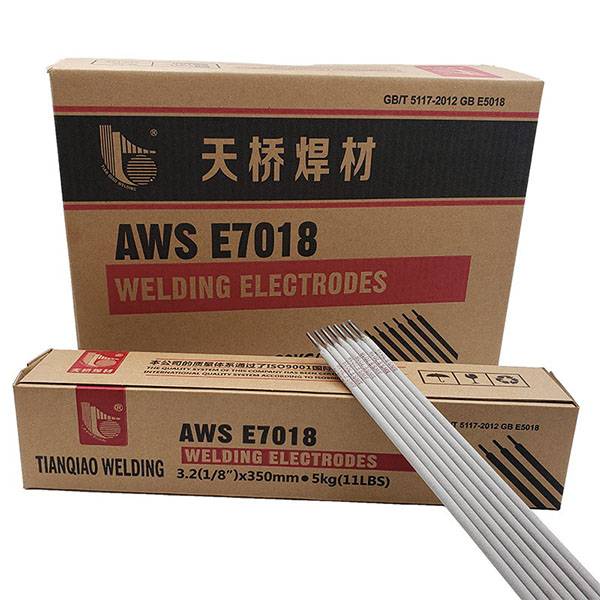

MIG Welding Wires |

|||||||||

|

Diameter |

Length |

Packing |

|||||||

|

Metric |

1.6mm |

2.0mm |

2.4mm |

3.2mm |

4.0mm |

4.8mm |

6.4mm |

457mm/914mm |

5kg/box 25kg/box 10kg/plasitc package |

|

British |

1/16″ |

5/64″ |

3/32″ |

1/8″ |

5/32″ |

3/16″ |

1/4″ |

||

|

18/36″ |

10lb/box 50lb/box 10kg/plasitc package |

||||||||

That has a sound business enterprise credit history, excellent after-sales assistance and modern production facilities, we now have earned an superb status among our buyers across the whole world for Factory Supply China Supplier Ercusn-C Welding Wire, We welcome new and previous shoppers from all walks of existence to contact us for long term organization relationships and acquiring mutual success!

Factory Supply China Ercusn-C, Welding Wire, With nearly 30 years’ experience in business, we’re confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.