Hot New Products Welding Consumables - Z308 Pure nickel cast iron electrode GB / T 10044 EZNi-1 AWS ENi-C1 JIS DFCNi – Tianqiao

Hot New Products Welding Consumables - Z308 Pure nickel cast iron electrode GB / T 10044 EZNi-1 AWS ENi-C1 JIS DFCNi – Tianqiao Detail:

APPLICATIONS:

It is suitable for the welding of thin pieces of cast iron welding and machining surfaces, such as cylinder heads, important gray cast iron engine blocks, gear boxes, and Machine Tool and soon.

CHARACTERISTICS:

THZ308 is pure nickel welding core, strong reduction of graphite type coating iron rod. It can be used in AC and DC dual purpose and is easy to operate. When welding, it is not necessary for weldment to preheat. It has good crack resistance and processability.

RECAUTIONS:

1. Before welding, the electrodes need to be baked for 1 hour with the temperature of 150±10℃ before using.

2 It can eliminate welding stress and avoid crack by hammering the welding seam.

3. In order to reduce the impurity elements in the base metal penetration weld, narrow white band width, improve crack resistance and processing properties, it should use small current welding in cast iron cold welding.

Chemical Composition of the deposited metal(the mass fraction): %

|

Elements |

C |

Si |

Mn |

S |

Fe |

Ni |

The mass of other elements |

|

Standard value |

≤2.0 |

≤2.5 |

≤1.0 |

≤0.03 |

≤8.0 |

≥90 |

≤1.0 |

Welding reference current: (AC,DC+)

|

Electrode diameter(mm) |

2.5 |

3.2 |

4.0 |

|

Welding current(A) |

60-90 |

90-110 |

120-150 |

Welding distortion correction:

For deformation correction in hot state, mechanical correction and hammering are strictly prohibited in the range of blue brittle temperature (300℃~500℃) to avoid brittle cracks.

Pay attention to the following requirements when the flame is locally heated

It is not advisable to repeat heating at the same part to avoid changes in the metallographic structure and mechanical properties of the steel.

Do not cause repeated corrections of tension and compression in the same part.

For hardenable welded parts, watering and rapid cooling are strictly prohibited.

Welding parts that need to be annealed should be rectified before annealing to eliminate internal stress during annealing. During annealing, the welded parts must be placed steadily so as not to deform again.

The flame straightening heating temperature can be 700℃~850℃ (fuchsia), and should not exceed 900℃ (bright red) for low alloy structural steel.

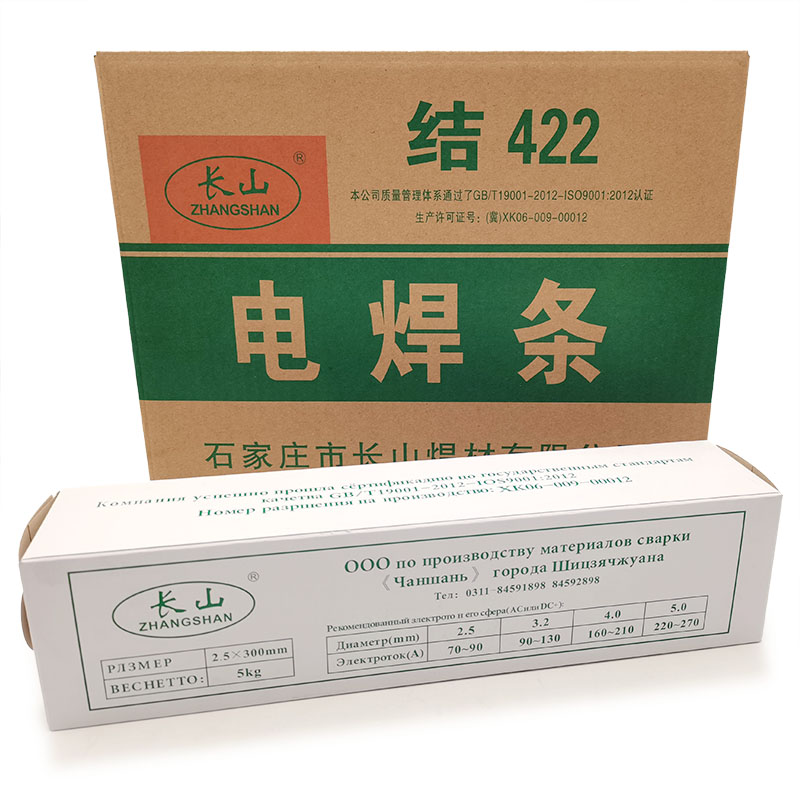

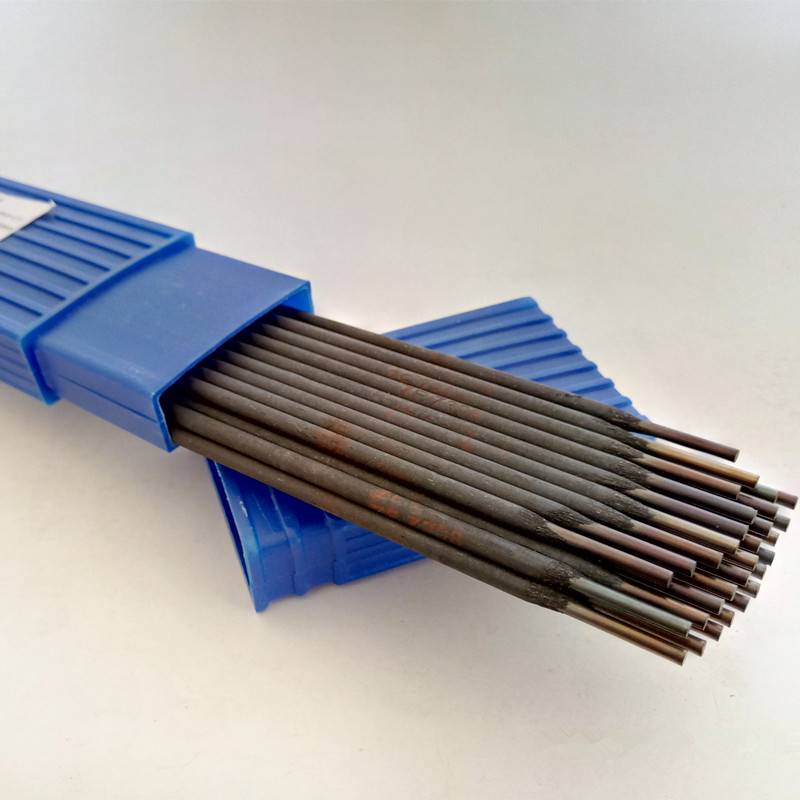

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for Hot New Products Welding Consumables - Z308 Pure nickel cast iron electrode GB / T 10044 EZNi-1 AWS ENi-C1 JIS DFCNi – Tianqiao, The product will supply to all over the world, such as: Lithuania, Kenya, Uruguay, Our items have national accreditation requirements for qualified, high quality goods, affordable value, was welcomed by people today all over the world. Our products will continue to enhance within the order and look forward to cooperation with you, Should really any of these products and solutions be of curiosity to you, be sure to letus know. We are likely to be content to offer you a quotation up on receipt of your detailed needs.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.