Low MOQ for Downhill Welding Electrode - Stainless Steel Welding Electrode AWS E309-16 (A302) – Tianqiao

Low MOQ for Downhill Welding Electrode - Stainless Steel Welding Electrode AWS E309-16 (A302) – Tianqiao Detail:

APPLICATIONS:

Suitable for welding the same type of stainless steel, stainless steel lining, different steels (such as Cr19Ni10 and low carbon steel, etc.) as well as gaoluo steel, high manganese steel, etc.

CHARACTERISTICS:

E309-16 is a Cr23Ni13 stainless steel electrode for rutile skin pressure equipment. Both ac and DC can be used for all position welding. Excellent welding performance. The deposited metal has good crack resistance and oxidation resistance.

ATTENTION:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. DC power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

CHEMICAL COMPOSITION OF ALL WELDING METAL: (Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

Cu |

|

Requirements |

≤0.15 |

0.5-2.5 |

≤1.00 |

≤0.03 |

≤0.04 |

12.0-14.0 |

122.0-25.0 |

≤0.75 |

≤0.75 |

|

Typical Results |

0.060 |

0.89 |

0.69 |

0.010 |

0.025 |

12.50 |

24.05 |

0.10 |

0.08 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

A/% |

| Requirements |

≥550 |

≥25 |

| Typical Results |

600 |

38 |

TYPICAL OPERATING PROCEDURES: (AC or DC+)

| Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

| Length (mm) |

300 |

300 |

350 |

400 |

400 |

| Current (A) |

25-50 |

50-80 |

80-110 |

110-160 |

160-200 |

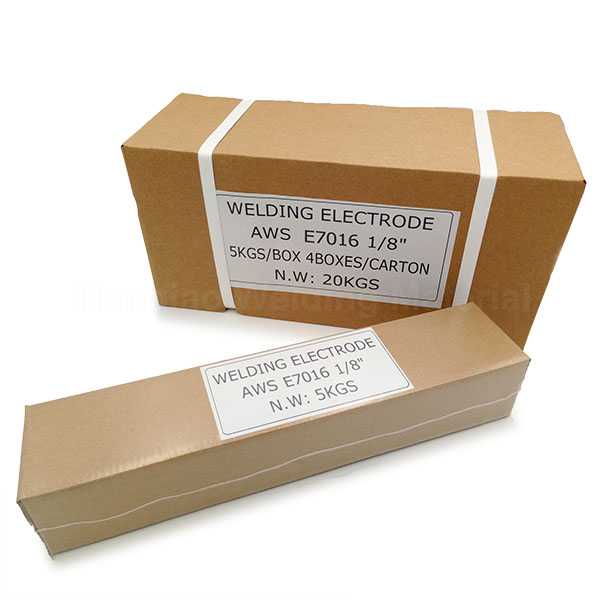

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

Rule inspection:

Welding parts are inspected by the quality inspection department of the manufacturer.

For welds that require radiographic testing, the length of the welds subject to radiographic testing should not be less than 20% of the full length of the welds.

When an impermissible defect in the weld is found, supplementary radiographic testing shall be performed near the defect, and the supplementary radiographic inspection length shall be equal to the length of the radiographically inspected part of the weld. If an unallowable defect is found after supplementary radiographic testing, all welds should be radiographically tested.

For important welding parts, the appearance and geometric shape and size of the weld shall be inspected one by one. In addition to the appearance inspection of welds for general parts, the geometry and dimensions of welds shall also be randomly inspected.

For important parts or important welds of important parts, the requirements for non-destructive testing or sealing test and welding mechanical performance test shall be carried out in accordance with the specifications in the drawings or ordering technical requirements.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Low MOQ for Downhill Welding Electrode - Stainless Steel Welding Electrode AWS E309-16 (A302) – Tianqiao, The product will supply to all over the world, such as: Mexico, Cologne, Danish, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!