Lowest Price for Cast Steel Welding Rod - Stainless Steel Welding Electrode AWS E316L-16(A022) – Tianqiao

Lowest Price for Cast Steel Welding Rod - Stainless Steel Welding Electrode AWS E316L-16(A022) – Tianqiao Detail:

|

Stainless steel welding electrode E316L-16 (A022) |

|

| APPLICATION | It is suitable for welding low carbon 00cr18ni9 stainless steel structure, also can be used to the corrosion resistance of stainless steel structure,such as the 0cr19ni11ti, whose working temperature below 300 ºC, it is mainly used for manufacture of synthetic fiber, fertilizer, oil and other equipment. |

| WELDING POSITIONS: | PA, PB, PC, PD, PE, PF |

| FEATURES: | Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, stable arc, little spatter, easy slag removal and good weld appearance. The deposited metal has good resistance to intergranular corrosion. |

| Attention: | |||||

| 1. The electrode must be re-dry by 320ºC-350ºC for 1 hour before welding. | |||||

| 2. The rust, oil, water and other impurities of the weld area must be removed before welding. | |||||

| 3. DC+ is better than AC, lower heat input is suggested, the temperature of preheat and interpass keep under 150ºC. | |||||

| Chemical Composition of All Weld Metal: (Wt. %) | |||||

| Items | C | Mn | Si | S | P |

| Requirements | ≤0.04 | 0.5-2.5 | ≤1.00 | ≤0.03 | ≤0.04 |

| Typical Results | 0.03 | 1.01 | 0.68 | 0.015 | 0.025 |

| Items | Ni | Cr | Mo | Cu | — |

| Requirements | 11.0-14.0 | 17.0-20.0 | 0.5-2.5 | ≤0.75 | — |

| Typical Results | 11.82 | 19.01 | 2.46 | 0.08 | — |

| Mechanical Properties of All Weld Metal: | |||||

| Items | Rm/MPa | A/% | |||

| Requirements | ≥490 | ≥25 | |||

| Typical Results | 580 | 45 | |||

| Typical Operating Procedures:(AC or DC+) | |||||

| Diameter (mm) | 2 | 2.5 | 3.2 | 4 | 5 |

| Length (mm) | 300 | 300 | 350 | 400 | 400 |

| Current (A) | 25-50 | 50-80 | 80-110 | 110-160 | 160-200 |

Our company has a strong technical force, reliable production technology, advanced production equipment, perfect testing methods, standardized management mechanism, and a high-quality workforce, which ensure the continuous improvement of production capacity and product quality. We have a complete sales team and have been committed to providing customers with efficient product supply support. Our company’s welding rod products have won the recognition and trust of customers with excellent quality, good reputation and sound service system.

For many years, our company has always adhered to the business strategy of “good welding rod, made with conscience”. Encouraged by the spirit of “high efficiency, low consumption, collaboration and innovation”, all employees are guided by the policy of “not for the best, but for the better”. Next, with the goal of creating a “famous brand”, we will use modern and cutting-edge management models to standardize the company, and strive to build the best and most advanced corporate culture that is compatible with the company, so that the company will become stronger first and then bigger. .

Exceeding quality is the eternal pursuit of “Tianqiao” welding consumables, so that customers of Tianqiao welding consumables can truly obtain assured products and value-for-money enjoyment.

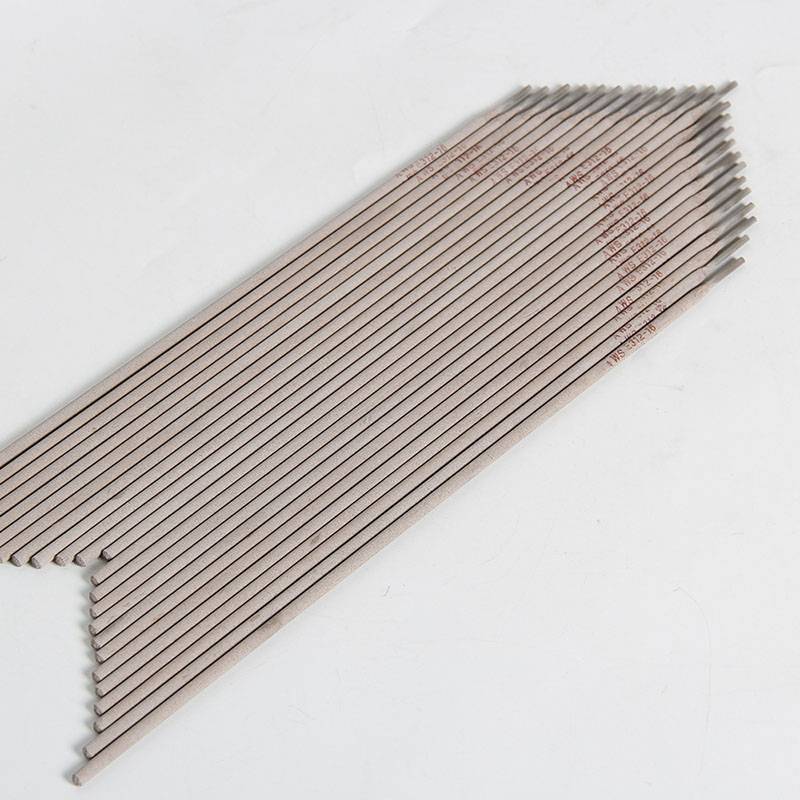

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We offer fantastic strength in high quality and enhancement,merchandising,income and marketing and procedure for Lowest Price for Cast Steel Welding Rod - Stainless Steel Welding Electrode AWS E316L-16(A022) – Tianqiao, The product will supply to all over the world, such as: Madagascar, Bangladesh, United States, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers' faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end goods, to do experienced products and solutions.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!