New Fashion Design for Welding Electrode 3.2 Mm - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao

New Fashion Design for Welding Electrode 3.2 Mm - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao Detail:

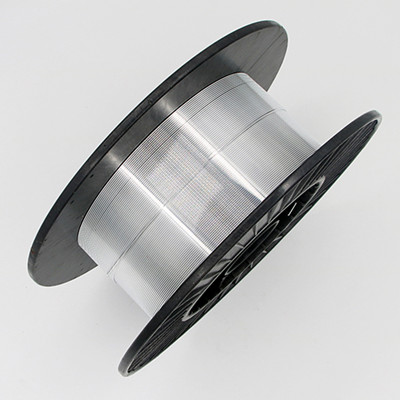

ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047

APPLICATION:

Used for jointing or overlay light alloy processing. It also widely used as filler materials in argon arc welding and oxyacetylene gas welding.

Argon arc welding is a perfect method for welding copper aluminum alloy.

Argon arc welding can not use flux, but oxyacetylene gas welding needs to use aluminum gas welding flux.

The selection of welding wire is mainly based on the type of base metal and the requirements of crack resistance, mechanical properties and corrosion resistance of the joint.

INTRODUCTION:

ER4047 is the eutectic aluminum silicon alloy welding wire with about12% Si element.

Suitable for Al-Si, Al-Si-Mg, Al Si mg Cu wrought aluminium and aluminium (7%Si) argon arc welding. Low melting point and good fluidity.

CHARACTERISTICS:

- Welding Filler Wire

- Spray and Flame Metallizing Wire

- Similar to AlSi12 (Germany), BS N21 (United Kingdom)

- Lower melting point and higher fluidity than 4043 wires

- Can be used as a substitute for 4043 wires to increase silicon in the weld metal, minimize hot cracking and produce higher fillet weld shear strength

- widely used for brazing of aluminum, Al-Mn, Al-Si-Mg alloy materials

SPECIFICATION:

MIG: 0.6mm; 0.8mm; 0.9mm; 1.0mm; 1.2mm; 1.6mm

TIG: 1.2mm; 1.6mm; 2.0mm; 2.4mm; 3.0mm; 4.0mm;

Typical Chemical Composition Of Deposited Metal:

| Cu | Si | Fe | Mn | Mg | Cr | Zn | Ti | Al | ||||||||

| 0.3 | 11.0-13.0 | 0.80 | 0.15 | 0.10 | 0.05 | 0.20 | - | Rem | ||||||||

Product detail pictures:

Related Product Guide:

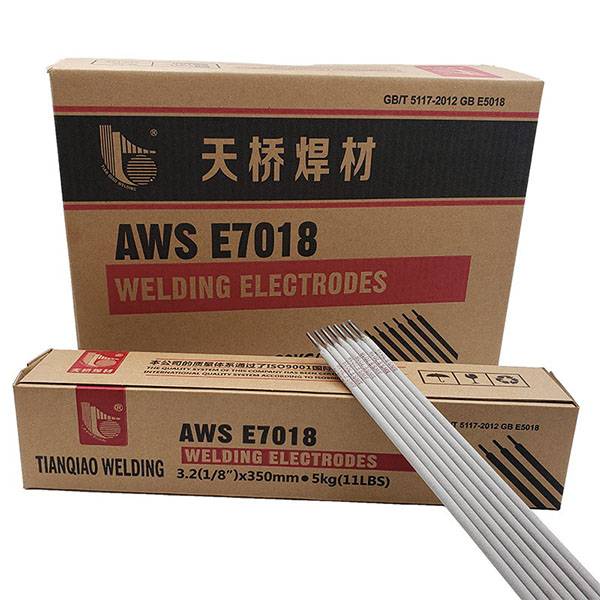

The composition of the welding electrode

Our pursuit and firm aim should be to Always fulfill our buyer requirements. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for New Fashion Design for Welding Electrode 3.2 Mm - ALUMINUM MIG WIRE TIG ROD Aluminum Alloy Welding Wire ER4047 – Tianqiao, The product will supply to all over the world, such as: Iceland, Karachi, Azerbaijan, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!