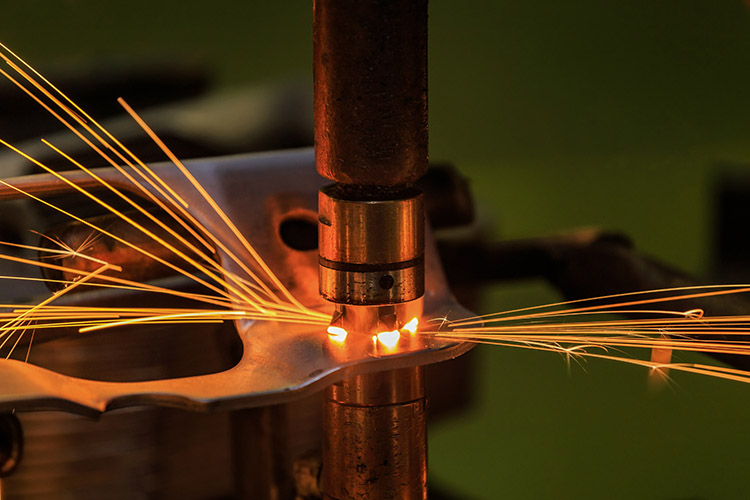

Spot welding is a resistance welding method in which the weldment is assembled into a lap joint and pressed between two electrodes, and the base metal is melted by resistance heat to form a solder joint.

Spot welding is mainly used in the following aspects:

1. Lap joint of sheet stamping parts, such as automobile cab, carriage, fish scale screen of harvester, etc.

2. Thin plate and section steel structures and skin structures, such as side walls and ceilings of carriages, trailer compartment panels, combine harvester funnels, etc.

3. Screens, space frames and cross bars, etc.

Characteristic

During spot welding, the weldment forms a lap joint and is pressed between two electrodes. Its main characteristics are as follows:

1. The heating time of the connection area is very short during spot welding, and the welding speed is fast.

2. Spot welding only consumes electric energy, and does not require filling materials or flux, gas, etc.

3. The quality of spot welding is mainly guaranteed by the spot welding machine. The operation is simple, the degree of mechanization and automation is high, and the productivity is high.

4. Low labor intensity and good working conditions.

5. Since the welding energization is completed in a short period of time, a large current and pressure are required, so the program control of the process is more complicated, the welding machine has a large capacity, and the price of the equipment is relatively high.

6.It is difficult to conduct non-destructive testing on solder joints.

Operation process

The surface of the workpiece should be cleaned before welding. The commonly used cleaning method is pickling cleaning, that is, pickling in heated sulfuric acid with a concentration of 10%, and then washing in hot water. The specific welding process is as follows:

(1) Send the workpiece joint between the upper and lower electrodes of the spot welding machine and clamp it;

(2) electrification, so that the contact surfaces of the two workpieces are heated and partially melted to form a nugget;

(3) Keep the pressure after the power is cut off, so that the nugget is cooled and solidified under pressure to form a solder joint;

(4) Remove the pressure and take out the workpiece.

Influencing factors

The main factors affecting welding quality are welding current and energization time, electrode pressure and shunt, etc.

1. Welding current and energization time

According to the size of the welding current and the length of the energization time, spot welding can be divided into two types: hard specification and soft specification. The specification that passes a large current in a short period of time is called a hard specification. It has the advantages of high productivity, long electrode life, and small deformation of the weldment. It is suitable for welding metals with better thermal conductivity. A specification that passes a smaller current for a longer period of time is called a soft specification, which has a lower productivity and is suitable for welding metals that tend to be hardened.

2. Electrode pressure

During spot welding, the pressure exerted by the electrode on the weldment is called electrode pressure. The electrode pressure should be selected appropriately. When the pressure is high, the shrinkage porosity and shrinkage cavity that may occur when the nugget solidifies can be eliminated, but the connection resistance and current density decrease, resulting in insufficient heating of the weldment and a decrease in the diameter of the nugget of the solder joint. The strength of the solder joint is reduced. The size of the electrode pressure can be selected according to the following factors:

(1) The material of the weldment. The higher the high temperature strength of the material. The greater the electrode pressure required. Therefore, when welding stainless steel and heat-resistant steel, the electrode pressure should be higher than that of low carbon steel.

(2) Welding parameters. The harder the weld specification, the greater the electrode pressure.

3. shunt

During spot welding, the current flowing from outside the welding main circuit is called shunt. The shunt reduces the current flowing through the welding area, resulting in insufficient heating, resulting in a significant decrease in the strength of the solder joint and affecting the welding quality. The factors that affect the degree of diversion mainly include the following aspects:

(1) The thickness of the weldment and the spacing of the solder joints. As the distance between solder joints increases, the shunt resistance increases and the degree of shunt decreases. When the conventional dot pitch of 30-50mm is adopted, the shunt current accounts for 25%-40% of the total current, and as the thickness of the weldment decreases, the degree of shunt also decreases.

(2) The surface condition of the weldment. When there are oxides or dirt on the surface of the weldment, the contact resistance between the two weldments increases, and the current through the welding area decreases, that is, the degree of shunt increases. The workpiece can be pickled, sandblasted or polished.

Safety Precautions

(1) The foot switch of the welding machine should have a solid protective cover to prevent accidental activation.

(2) The operating point shall be equipped with a baffle to prevent the splashing of working sparks.

(3) Welders should wear flat protective glasses when welding.

(4) The place where the welding machine is placed should be kept dry, and the ground should be covered with anti-skid boards.

(5) After the welding work, the power supply should be cut off, and the cooling water switch should be extended for 10 seconds before closing. When the temperature is low, the accumulated water in the waterway should be removed to prevent freezing.

Post time: Jul-31-2023