The coating plays a complex metallurgical reaction and physical and chemical changes in the welding process, which basically overcomes the problems in the welding of the photo electrode, so the coating is also one of the main factors to determine the quality of the weld metal.

Electrode coating:Refers to the coating layer of fine granular material with different physical and chemical properties uniformly coated on the surface of the welding core.

The role of welding electrode coating: In the welding process, it forms slag with appropriate melting point, viscosity, density, alkalinity and other physical and chemical properties, to ensure stable arc combustion, make the droplet metal easy transition, create an atmosphere around the arc zone and molten pool to protect the welding area, and obtain good weld formation and performance.By adding deoxidizer, alloying element or certain content of iron powder to the coating, it can also meet the requirements of weld metal performance or improve the melting efficiency.

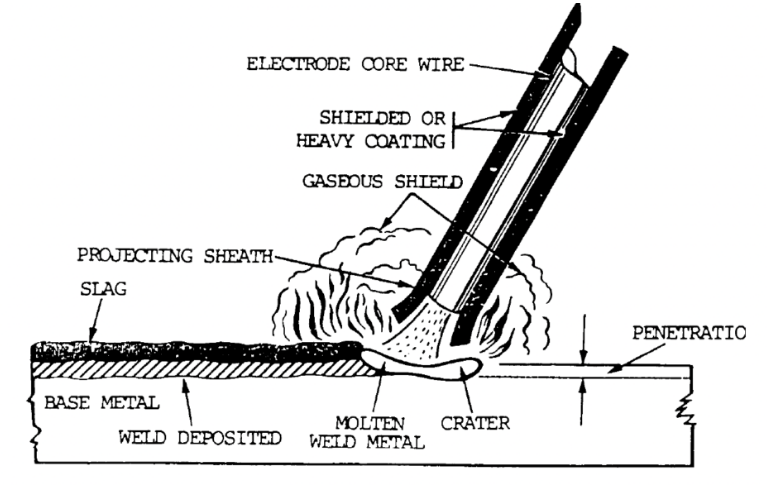

Principle of electrode arc welding:

1. Medicine skin

2. Weld core

3. Protect gas

4: Arc

5. Molten pool

6. Base material

7. Weld

8. Welding slag

9. Slag

10. Melt drops

Various raw materials according to their role in the electrode coating can be divided into:

(1) Arc stabilizer

The main function is to make the electrode easy to start arc and keep the arc stable combustion in the welding process. As arc stabilizer raw materials are mainly some containing a certain number of low ionization potential easily ionizing elements, such as feldspar, sodium silicate, rutile, titanium dioxide, marble, mica, ilmenite, reduced ilmenite and so on.

(2) Gas making agent

Under the action of high temperature arc decomposition gas, forming a protective atmosphere, protect arc and molten metal, prevent the intrusion of oxygen and nitrogen in the surrounding air. Commonly used gas-making agents are carbonate (such as marble, dolomite, rhombic acid, barium carbonate, etc.) and organic matter (such as wood powder, starch, cellulose, resin, etc.).

(3) Deoxidizer (also known as reducing agent)

The oxygen content in weld metal can be reduced and the performance of weld metal can be improved by chemical metallurgical reaction in welding process. Deoxidizer mainly contains elements of iron alloy and metal powder with great affinity for oxygen. Commonly used deoxidizer are ferromanganese, ferrosilicon, ferrotitanium, ferroaluminum, silicon calcium alloy, etc.

(4) Plasticizer

It’s main function is to improve the plasticity, elasticity and fluidity in the process of electrode being pressed coating , improve the coating quality of the electrode, so that the smooth surface of the electrode coating does not crack. Usually select a certain elasticity, slippery or absorbent after a certain expansion characteristics of materials, such as mica, white mud, titanium dioxide, talc, solid water glass, cellulose, etc.

(5) Alloy agent

It is used to compensate the burning of alloying elements in the welding process and to transfer alloying elements to the weld, so as to ensure the chemical composition and properties of the weld metal. According to the need to choose a variety of ferroalloys (such as ferromanganese, ferrosilicon, ferrochrome, iron and steel, ferric vanadium, ferric niobium, ferric boron, rare earth ferrosilicon, etc.) or pure metals (such as manganese metal, chromium metal, nickel powder, tungsten powder, etc.).

(6) Slag making agent

Welding can form a certain physical and chemical properties of molten slag, protect the welding droplet and molten pool metal, improve weld formation, as a slagging agent of raw materials are marble, fluorite, dolomite, magnesia, feldspar, white mud, mica, quartz, rutile, titanium dioxide, ilmenite, etc.

(7) Binder

The coating material is firmly bonded to the welding core, and the electrode coating has a certain strength after drying. In the process of welding metallurgy, there is no harmful effect on weld pool and weld metal. Commonly used binders are sodium silicate (potassium, sodium and mixed sodium silicate) and phenolic resin, gum, etc.

Post time: May-04-2023