With the rapid development of the petrochemical industry, stainless steel materials have been widely used, which has also put forward higher requirements for the welding of pipes and plates. The previous stainless steel arc welding primer method has been gradually eliminated, and argon arc welding is used for primer welding.

Argon arc welding primer is cleaner and faster than arc welding primer. At the same time, there are some problems.

During the welding process, since the back of the stainless steel argon arc welding base is easily oxidized and causes defects, back protection measures must be taken to ensure the mechanical properties and corrosion resistance of the weld. Therefore, effective protection must be taken when welding stainless steel.

Today we introduce several commonly used stainless steel welding back protection methods:

01

Back Argon Protection Method

Commonly used protective gases can be divided into simple argon gas protection and mixed gas protection. A certain proportion of argon-nitrogen mixed gas is more conducive to austenitic stainless steel welding. Some inert gases are not used because of their high cost.

Argon filling method protection is a relatively traditional back protection method, which has the characteristics of better back protection, easy to master, high cleanliness, and high pass rate. It is divided into protective cover argon filling protection method, local argon filling protection method, direct filling of welding joint, argon welding protection method, etc.

1. Protective cover filled with argon protection method

This method is often used in stainless steel welding of plates and large-diameter pipes. The protective cover is connected to a metal pipe and an argon gas hose. The argon gas valve is opened to fill the protective cover with argon gas.

Another person is required to hold the metal pipe as a handle so that the protective cover slides on the molten pool on the back in synchronization with the external welding of the plate or pipe.

In this way, the back side is effectively protected, and the protection is concentrated. The argon gas does not need to be opened too much, and the argon gas is wasted less.

2. Local argon filling protection

It is easy to use local protection for pipelines with smaller local space and shorter dimensions.

Method: Seal the welding joint of the pipe with tape (to prevent air leakage). Seal both ends of the pipe with sponge, rubber, paper shell, etc. Insert the argon hose from one end and fill it with argon. The other end of the pipe is best sealed. Drill a small hole (no need for sponge), which will facilitate the final welding joint and will not cause dents due to excessive internal pressure.

During welding, in order to prevent a large amount of argon gas from being discharged from the weld seam, the weld sealing tape should be torn off and welded in sections, which can reduce further loss of argon gas and effectively protect the weld seam. Features are wasted, argon charging is slow, cost is too high, etc.

3 .Direct argon filling protection method for the welding joint

For pipelines that are too long and have slightly larger diameters, local argon filling is too wasteful, the quality cannot be guaranteed, and the project cost is too high. In order to save costs, the direct argon filling method at the welded joint can be used.

Method of making plugs on both sides of weld seam

Process the sponge into a plug with a slightly larger diameter for the pipe and connect the two pieces of sponge with a wire at a distance of 300-400mm to form a double plug. One end of the plug is connected to a longer piece of steel wire.

When matching, put the plugs at 150-200mm on both sides of the weld to be welded. The long iron wire at one end should be longer than the length of the pipe at one end of the weld and expose the pipe end. One end of the small metal pipe should be flattened and the other end should be connected to the argon hose. Insert the flattened end into the aligned weld and fill it with argon. The best insertion direction is the uppermost part, so that before the final joint of the bottom weld, the small tube can be pulled out and welded by the remaining gas in the pipe. After welding, use wire to pull out the plug.

Water soluble paper protection method

Before assembly, affix water-soluble paper at 150-200mm on both sides of the welding joint as a seal. After alignment, use the same inflatable welding method as the sponge plug. When the pipeline is tested for hydraulic pressure, the water-soluble paper will dissolve and be discharged with the water.

4. Argon gas protection judgment

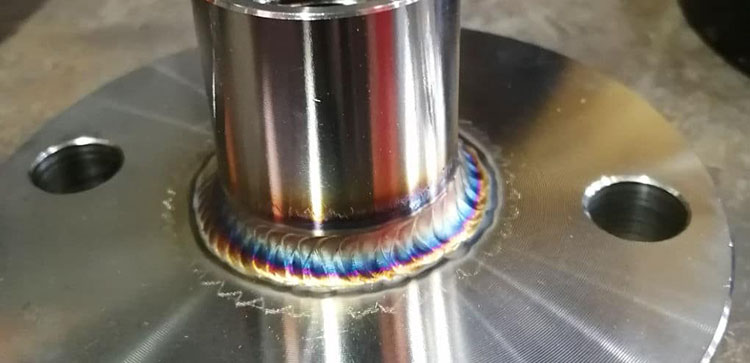

The protective effect of argon gas can be judged according to the color of the internal weld, so that the operator can adjust the argon gas according to the color to achieve the best protection effect. The colors are white and golden, and gray and black are the worst.

5. Precautions for Stainless Steel Back Protection

(1) Before argon arc welding, the back of the weldment should be protected by filling it with argon in advance. The flow rate should be larger. After the air is discharged, the flow rate will gradually decrease. During the welding process, the pipe should be filled with argon continuously. The argon hose can be unplugged only after welding is completed so that the weld is well protected.

In addition, special attention should be paid to the fact that welding can only be carried out after the air is exhausted, otherwise the protective effect of argon filling will be affected.

(2) The argon gas flow rate should be appropriate. If the flow rate is too small, the protection is not good, and the back of the weld is easily oxidized; if the flow rate is too large, defects such as concavity of the root of the weld will be caused, affecting the welding quality.

(3) The argon gas inlet should be placed as low as possible in the closed section, and the air discharge hole should be placed slightly higher in the closed pipe section. Because argon is heavier than air, filling the argon from a lower position can ensure a higher concentration, and the protective effect of argon filling will be better.

(4) In order to reduce the loss of argon gas in the pipe from the gap between the joints, which affects the protection effect and increases the cost, tape can be affixed along the gap between the welding joints before welding, leaving only the length for one continuous welding by the welder, and removing the tape while welding.

02

Self-shielding welding wire protection method

The self-protected welding wire on the back is a welding wire with a coating. During welding, its protective coating will participate in the complete protection of the front and back of the molten pool, forming a dense protective layer to prevent the back of the weld bead from being oxidized. This protective layer will automatically fall off after cooling, and will be purged and tested during the pressure test. will be cleared.

The use method of this kind of welding wire is basically the same as that of ordinary argon arc welding solid core wire, and the performance of the weld metal can meet the requirements.

The self-protecting welding wire is not restricted by various welding conditions, making welding preparation faster and easier. However, due to the coating on the surface of the welding wire, there will be some discomfort when the welding personnel operate it.

Due to the incompatibility and welding techniques not suitable for coated welding wires, defects such as concavities sometimes occur. Therefore, there are certain requirements for the welding personnel’s operating skills and techniques. Self-shielding wire is best used for primers due to its high cost.

In addition, there are many brands of self-shielding welding wires on the market to choose from, and their applicability is also different.

Post time: Sep-21-2023