During fusion welding, under the action of the welding heat source, the liquid metal part with a certain geometric shape formed on the weldment by the molten electrode metal and the partially molten base metal is the molten pool. After cooling, it becomes a weld, so the temperature of the molten pool directly affects the welding quality.

If the temperature of the molten pool is high, the molten pool is large, and the molten iron has good fluidity, the fusion zone is easy to fuse; but when the temperature is too high, the molten iron is easy to drip, and the back side of single-sided welding and double-sided forming is easy to burn through, form weld bumps, and shape. It is difficult to control, and the plasticity of the joint is reduced, and the joint is easy to crack; when the temperature of the molten pool is low, the molten pool is small, the molten iron is darker, and the fluidity is poor. It is easy to produce defects such as incomplete penetration, lack of fusion, and slag inclusion.

Therefore, effectively controlling the temperature of the molten pool is very important to ensure the welding effect and the quality of the finished product.

Figure 1 Tianqiao welding

The temperature of the molten pool is closely related to the welding current, the diameter of the electrode, the method of transportation, the angle of the electrode, and the arc burning time. The following measures are taken to control the temperature of the molten pool according to the relevant factors.

1. Welding current and electrode diameter

These two aspects are important factors for welding, and the two also have an inseparable bond. During fusion welding, the current flowing back through the weldment is called welding current. The diameter of the electrode refers to the cross-sectional size of the filler metal rod. In simple terms, whether the welding rod can be properly melted is determined by the current passed.

If the current is too small, it is difficult to start the arc, the electrode is easy to stick to the weldment, the fish scales are thick, and the two sides are not fused; if the current is too large, the splash and smoke during welding will be large, the electrode will be red, and the surface of the molten pool will be very bright. It is easy to burn through and undercut; when the current is appropriate, it is easy to ignite and the arc is stable, the splash is small, the uniform crackling sound can be heard, the two sides of the welding seam smoothly transition to the base material, the surface fish scales are very thin, and the welding slag is easy Knock out. In terms of its application, there are complicated relationships.

1.1 Select the welding current and electrode diameter according to the space position of the weld

In the vertical, horizontal and upright positions, the current is correspondingly smaller than that of flat welding, and the current should usually be about 10% smaller than that of flat welding.

Similarly, in the vertical, horizontal, and upright positions, the diameter of the electrode is usually smaller than that of the flat welding. For example, in the flat welding of a flat plate larger than 12mm, the 5.0mm electrode is often used. , And there is almost no electrode with a diameter of 5.0mm in the vertical, horizontal and upright positions.

1.2 The welding current and electrode diameter are selected according to the welding level of the weld.

For example, for 12mm flat plate butt joints, 3.2mm Tianqiao electrodes are generally used for the bottom layer of flat welding, and the welding current is 90-110A, and 4.0mm Tianqiao electrodes can be used for the filling and cover layer, and the welding current is 160-175A.

Therefore, a reasonable selection of the welding current and the diameter of the electrode can easily control the temperature of the molten pool, which is the basis for a good weld formation. If the welding current is too small, the temperature of the weld pool is too low, causing the arc to be unstable, and the workpiece may not be welded through. If the welding current is too high and the temperature of the molten pool is too high, it will cause serious splashing and flow of molten metal, and even burn through the workpiece to form welding bead.

The relationship between the welding current and the diameter of the electrode is listed below. You can make a reasonable choice based on your own experience or habits. You don’t need to determine the same parameters as others, as long as you feel it is suitable and ensure a good weld formation.

2. Transportation of welding rod

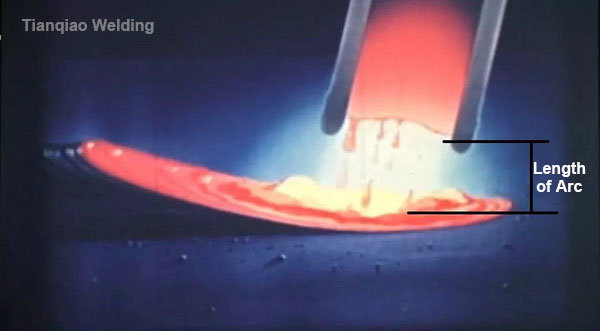

The welding rod is fed in the direction of the molten pool along the axis. After the welding rod is melted, the length of the arc can continue to be maintained. Therefore, the speed of the welding rod in the direction of the molten pool is required to be equal to the melting speed of the welding rod.

If the feeding speed of the electrode is lower than the melting speed of the electrode, the length of the arc will gradually increase, resulting in arc interruption; if the feeding speed of the electrode is too fast, the length of the arc will be shortened rapidly, and the end of the electrode will be short-circuited in contact with the weldment. Extinguish the arc.

Figure 2 Tianqiao welding

3. Angle of delivery and feeding position

During welding, the angle of the electrode should change with the welding position, and always keep the temperature of the molten pool on both sides of the blunt edge appropriate. If the temperature is too high, it will cause burn-through, and if it is too low, it will cause the phenomenon of insufficient penetration and fusion. When the angle between the electrode and the welding direction is 90 degrees, the arc is concentrated and the temperature of the molten pool is high;

If the angle becomes smaller, the arc will be dispersed and the temperature of the molten pool will be lower. For example, if the bottom layer of the 12mm flat welding seal, if the welding rod angle is 50-70 degrees, the temperature of the molten pool will be lowered at this time, and the phenomenon of welding bead or rise on the back side is avoided. For another example, after changing the welding rod at the bottom of the 12mm plate vertical welding seal, we use a 90-95 degree welding rod angle when transporting the welding rod, so that the temperature of the molten pool can be quickly increased, the molten hole can be opened smoothly, and the back surface is formed relatively flat, which can be effectively controlled. The phenomenon that the joint point is concave.

If the electrode feed position is not enough, it will cause insufficient penetration or groove clamping. Because the arc is relatively dispersed at this time, the melting temperature of the blunt edge of the base material is not enough, resulting in the unfusion of the base material at the bottom; if you want to fully melt the metal, you must increase the melting time. Welding, multi-layer superposition of molten pool will produce slag inclusion phenomenon.

The correct method is to extend the welding rod into the blunt edge groove at an angle of 75 degrees, align the groove base material to melt and swing on both sides, each action takes about 1 second, so far the first molten pool is formed, and then enters the next The formation of a molten pool. At this time, the melting time of each molten pool is short and the weight is light, and it is not suitable to cause falling, and the welding bump will not form. The shallow groove is also conducive to the welding of the cover surface.

The latter molten pool covers 2/3 of the previous one. Each molten pool is thinner, and the latter plays a post-heat melting effect on the previous one, ensuring that the gas in the molten pool has sufficient time to overflow and prevent it from being generated. Stomata.

Figure 3 Tianqiao welding

4. Arc burning time

In the practice teaching of horizontal and vertical fixed welding of 57×3.5 pipes, the arc-breaking method is used for welding. When starting welding, the temperature of the base metal is low. If the welding rod is not placed to the edge of the groove, the molten iron will quickly shrink back and produce undercuts. The weld formation will also be high and narrow, which will not achieve the effect of excessive smoothness, and it is easy The resulting surface is not fused.

Analyzing from the shape of the molten pool, if it is in the shape of a falling droplet, the welded shape is definitely not good, and welding bead may occur. Therefore, the welding point should be fully preheated from the overhead welding. The angle between the electrode and the pipe is 75 degrees. After the arc is ignited, the arc is stretched for preheating. After the first drop of molten iron on the electrode head falls, the electrode is sent in.

The temperature of the molten pool at this time should ensure that the size of the molten pool is the groove width plus about 1 mm, so that the base material can be fully melted into the droplet to form a weld.

In the actual welding operation, it is necessary to learn to observe the changes in the temperature of the molten pool and to master the method of effectively controlling the temperature of the molten pool, which is the basis for learning welding technology. It is necessary to be able to judge the welding rod angle, feeding position and melting time according to the molten pool of each part, quickly grasp the operation technology of several key parts, and after a period of actual training, the technical level will improve rapidly, and the occurrence rate of various welding defects Significantly lower, improve the strain capacity in complex construction welding, which is conducive to the improvement of welding technology in the future.

Post time: Jul-15-2021