-

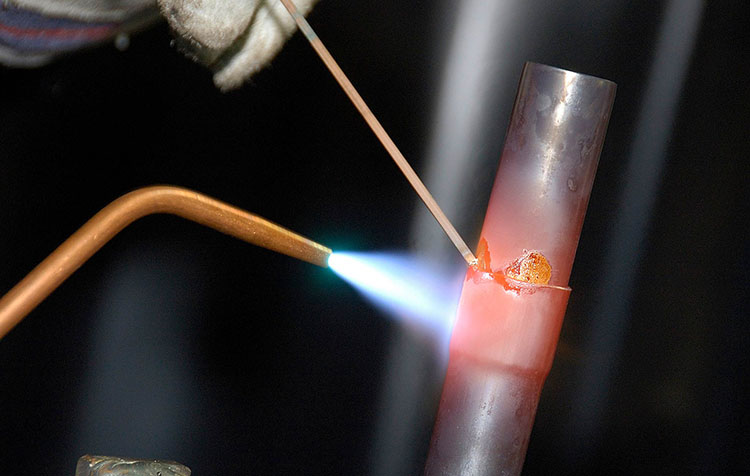

The energy source of brazing can be chemical reaction heat or indirect heat energy. It uses a metal with a melting point lower than that of the material to be welded as the solder. After heating, the solder melts, and the capillary action pushes the solder into the gap between the contact surface... Read more »

-

Knowledge point 1: Influencing factors and countermeasures of welding process quality Process quality refers to the degree of guarantee of product quality in the process of production. In other words, the quality of the product is based on the quality of the process, and it must have excellent pr... Read more »

-

1. Reduce stress concentration The stress concentration point of the fatigue crack source on the welded joint and structure, and all means of eliminating or reducing stress concentration can improve the fatigue strength of the structure. (1) Adopt a reasonable structural form ① Butt joints are pr... Read more »

-

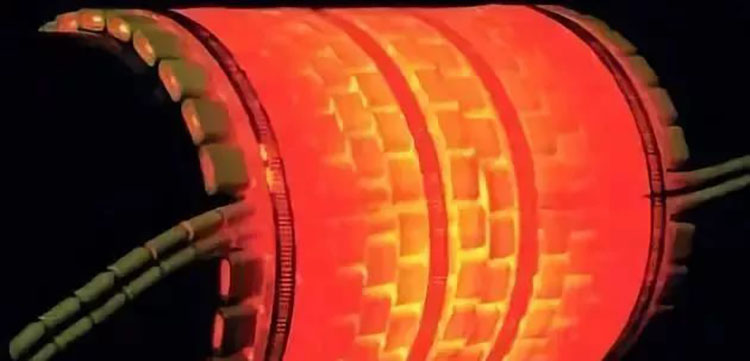

The submerged arc welding process is the most ideal choice in the important application fields of pipelines, pressure vessels and tanks, track manufacturing and major construction. It has the simplest single wire form, double wire structure, series double wire structure and multi wire structure. ... Read more »

-

The welding residual stress is caused by the uneven temperature distribution of the weldment caused by welding, the thermal expansion and contraction of the weld metal, etc., so the welding construction will inevitably produce residual stress. The most common method to eliminate residual stress i... Read more »

-

1. The priority principle of arc welding with electrodes For the installation and welding of pipelines whose diameter is not too large (such as below 610mm) and the length of the pipeline is not very long (such as below 100km), electrode arc welding should be considered as the first choice. In... Read more »

-

1.How to weld mild steel? Low carbon steel has low carbon content and good plasticity, and can be prepared into various forms of joints and components. In the welding process, it is not easy to produce hardened structure, and the tendency to produce cracks is also small. At the same time, it is ... Read more »

-

Harmful factors of welding materials, what should be paid attention to when using welding materials?

Harmful factors of welding materials, what should be paid attention to when using welding materials?Harmful factors of welding materials (1) The main research object of welding labor hygiene is fusion welding, and among them, the labor hygiene problems of open arc welding are the biggest, and the problems of submerged arc welding and electroslag welding are the least. (2) The main harmful fa... Read more »

-

Ⅰ. Start up 1. Turn on the power switch on the front panel and set the power switch to the “ON” position. The power light is on. The fan inside the machine starts to spin. 2. The selection switch is divided into argon arc welding and manual welding. Ⅱ. Argon arc weld... Read more »

-

1. What is the purpose of steel annealing? Answer: ①Reduce the hardness of steel and improve plasticity, so as to facilitate cutting and cold deformation processing; ②Refine the grain, uniform the composition of steel, improve the performance of steel or prepare for future heat treatment; ③Elimin... Read more »