-

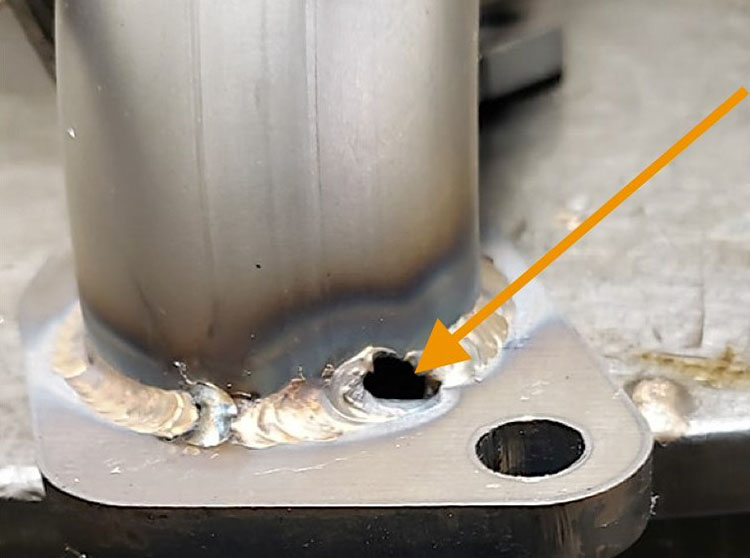

The so-called welding skills are simple welding methods, correct electrode angle and operation, and your welds will not be too bad. At the beginning of welding, due to the lack of mastery of the welding rhythm and unskilled handling techniques, it will cause pauses. If it is deeper and shallower,... Read more »

-

Welding can use AC or DC welding machine. When using a DC welding machine, there are positive connection and reverse connection. Factors such as the electrode used, the condition of the construction equipment, and the welding quality should be considered. Compared with AC power supply, DC power s... Read more »

-

Welding current, voltage and welding speed are the main energy parameters that determine weld size. 1. Welding current When the welding current increases (other conditions remain unchanged), the penetration depth and residual height of the weld increase, and the melting width does not change much... Read more »

-

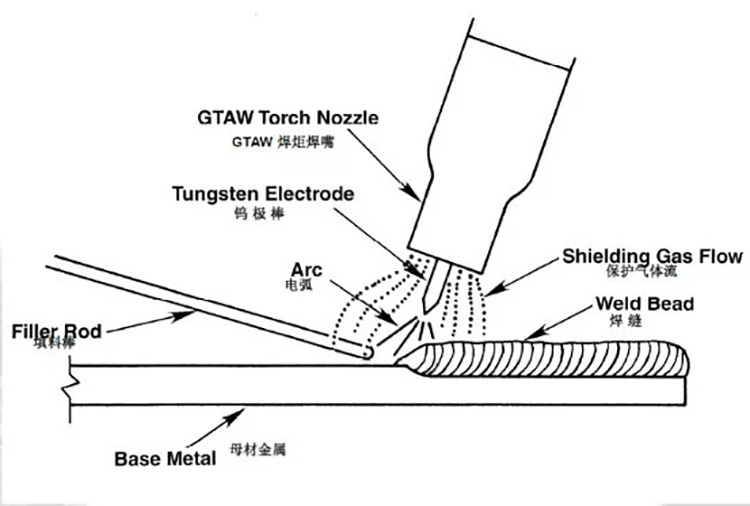

Red head thoriated tungsten electrode (WT20) Currently the most stable and widely used tungsten electrode is mainly used in the welding of carbon steel, stainless steel, silicon copper, copper, bronze, titanium and other materials, but it has slight radioactive pollution. Gray head cerium tungst... Read more »

-

Argon tungsten arc welding uses argon as a shielding gas to heat and melt the welding material itself (it is also melted when the filler metal is added) by means of the arc generated between the tungsten electrode and the weld body, and then forms the welding of the weld metal Way. The tungsten e... Read more »

-

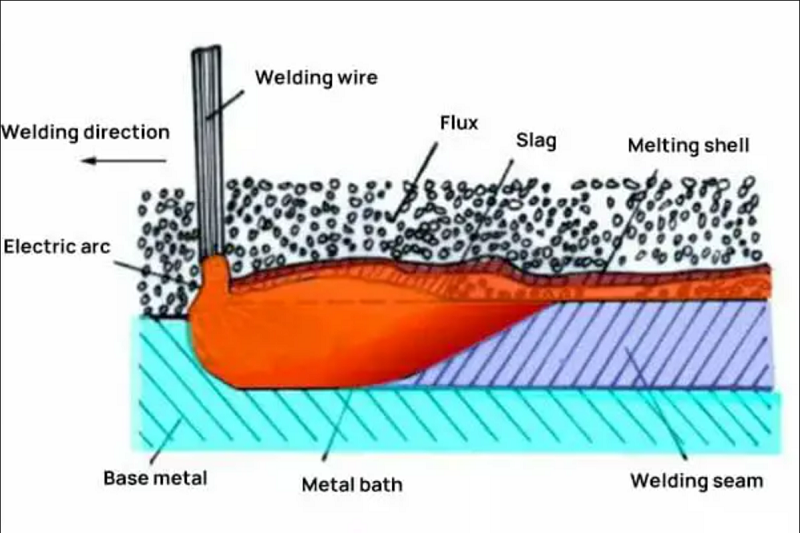

What is flux-cored arc welding? Flux-cored wire arc welding is a welding method that uses the arc between flux-cored wire and workpiece to heat, and its English name is simply FCAW. Under the action of arc heat, welding wire metal and workpiece are connected by melting, forming a weld pool, arc f... Read more »

-

When welding stainless steel, the performance of the electrode must match the purpose of the stainless steel. Stainless steel electrode must be selected according to the base metal and working conditions (including working temperature, contact medium, etc.). Four types of stainless steel as well ... Read more »

-

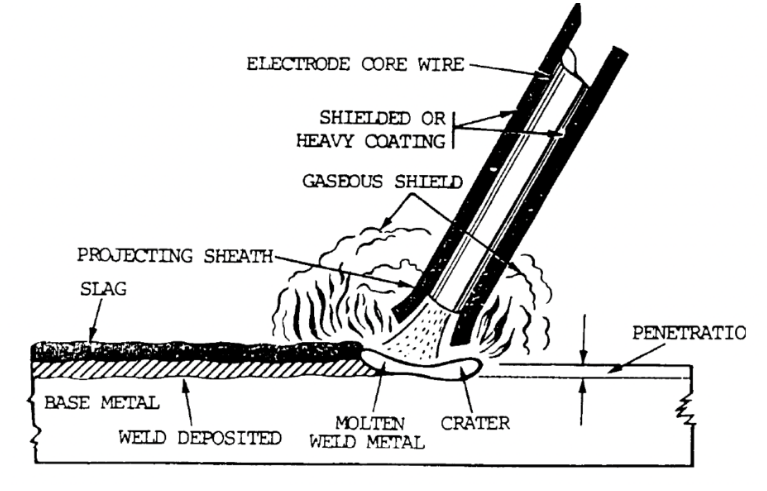

The coating plays a complex metallurgical reaction and physical and chemical changes in the welding process, which basically overcomes the problems in the welding of the photo electrode, so the coating is also one of the main factors to determine the quality of the weld metal. Electrode coating:... Read more »

-

– FLUX– Flux is a granular welding material. During welding, it can be melted to form slag and gas, which plays a protective and metallurgical role on the molten pool. Constituent Flux is composed of marble, quartz, fluorite and other ores and titanium dioxide, cellulose and oth... Read more »

-

Welding is a process in which the materials of the workpieces to be welded (the same or different) are combined by heating or pressure or both, and with or without filling materials, so that the materials of the workpieces are bonded between atoms to form a connection. So what are the key points... Read more »