-

TIG 1.Application : TIG welding (tungsten argon arc welding) is a welding method in which pure Ar is used as a shielding gas and tungsten electrodes are used as electrodes. TIG welding wire is supplied in straight strips of a certain length (usually lm). Inert gas shielded arc welding using... Read more »

-

Welding work involves many industrial fields, welding fume is one of the most common hazards of welding work. Welding fume is in the welding process when the welding rod and welding parts in contact, in the case of high temperature combustion generated a kind of fume, this fume contains manganese... Read more »

-

Dear Friends! Much joy to you in the up coming year. May the warmest wishes, happy thoughts and friendly greetings come at New Year and stay with you all the year through! electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode... Read more »

-

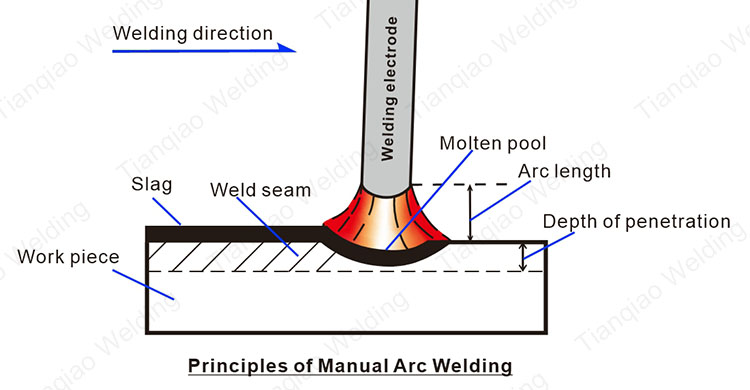

SMAW, also be well known as electrode arc welding, is a fusion welding method in which the arc is induced by the electrode and the welding parts are melted by the arc heat. It is the most widely used and common welding method at present. Arc is an air conduction phenomenon. The welding arc is a ... Read more »

-

Consider the physical properties, mechanical properties and chemical composition of the weld material 1. Structural steel welding, generally consider the principle of equal strength, choose to meet the requirements of the mechanical properties of the joint welding material. 2. For low carbon ... Read more »

-

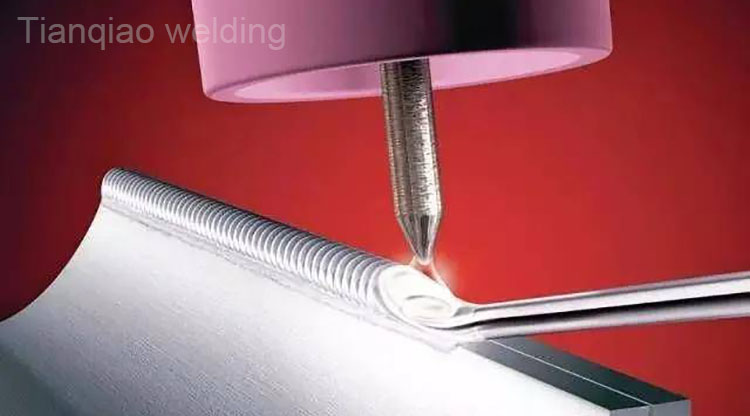

Tungsten argon arc welding is a kind of arc welding method using argon or argon rich gas as protection and tungsten electrode as electrode, which is referred to as GTAW(Gas Tungsten Arc Weld) or TIG(Tungsten Inert Gas Welding) for short. During welding, the shielding gas is continuously sprayed... Read more »

-

The preparation work before welding is as important as the welding process, which is directly related to the welding quality and effect of the finished product. 1. Electrode drying The purpose of drying the electrode before welding is to remove the moisture in the wet electrode and reduce the hy... Read more »

-

The welding electrodes that leave the factory have been dried at high temperature and packaged with moisture-proof material, which usually prevents the coating from absorbing moisture. However, during the long-term storage of the electrode, the moisture absorption of the electrode coating is inev... Read more »

-

Tianqiao welding materials company is an enterprise that produces welding materials. The development and growth of our company are inseparable from the great assistance of our customers and friends. As this new year is approaching, all employees of tianqiao welding company: We wish you all good c... Read more »

-

The welding parameters of electrode arc welding mainly include electrode diameter, welding current, arc voltage, number of welding layers, power source type and polarity, etc. 1. Selection of electrode diameter The choice of electrode diameter mainly depends on factors such as the thickness of th... Read more »