In today’s world where welding technology is changing with each passing day, Shielded Metal Arc Welding (SMAW) is still active in the industrial field with its unique vitality. From steel structure welding of skyscrapers to emergency repairs of field oil pipelines, this process, which was born in the late 19th century, is still the most familiar old friend of welders around the world due to its simple and reliable characteristics.

Shielded Metal Arc Welding (SMAW) is a welding process that uses the arc heat generated between the electrode and the workpiece to melt the metal to form a weld. Its core equipment includes a welding machine, welding tongs and a welding rod coated with a coating on the outer layer. Its basic principle is to trigger an arc through the contact between the electrode and the workpiece. The arc temperature can reach more than 5000°C, so that the electrode metal and the base material melt to form a molten pool, and then the molten pool cools and solidifies to form a welded joint.

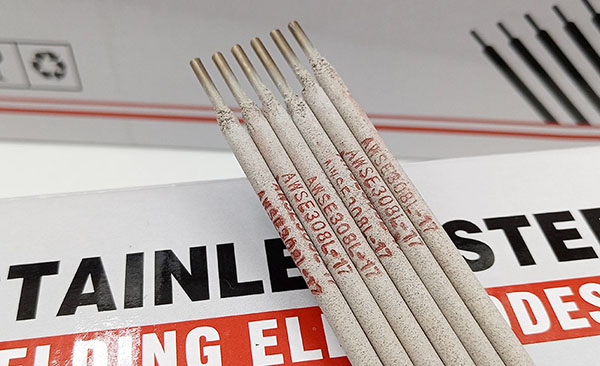

During SMAW welding, the welder only needs to insert the electrode into a handheld welding tongs, and the arc melts the electrode and the workpiece surface to achieve welding. This welding method does not require external shielding gas, because the electrode itself contains a coating of minerals and metals. During the welding process, the coating decomposes under the high temperature of the arc to produce gas and slag, which plays a role in isolating the air and protecting the molten pool, thereby avoiding oxidation and pollution. In addition, since the welding equipment is simple and portable, the SMAW welding method is suitable for welding operations in various environments and positions. During the operation, the welding current, voltage, speed and angle need to be controlled. For example, when welding thick plates, a higher current is required to increase the penetration depth, while when welding thin plates, the current needs to be reduced to avoid burn-through.

Advantages and disadvantages of SMAW

(I) Advantages

Simple equipment and low cost: only a welding machine, welding tongs and welding rod are required to complete welding, without complex auxiliary equipment, suitable for small workshops or field operations.

Strong adaptability: All-position welding (horizontal, vertical, overhead welding, etc.) can be achieved. For example, it is often used to weld the welds of complex structures inside the cabin in ship construction.

Wide material compatibility: It can weld a variety of metals such as carbon steel, stainless steel, cast iron, copper alloy, etc. Typical applications include pressure vessel repair, steel structure bridge connection, etc.

(II) Disadvantages

Low efficiency: frequent replacement of welding rods and slow welding speed. For example, compared with submerged arc welding (SAW), SMAW takes more than 30% longer to weld thick plates.

High labor intensity: welders need to hold the welding clamp for a long time, which is easy to fatigue, and they need to withstand high temperature and smoke hazards.

Quality depends on operating skills: the quality of welds is greatly affected by the experience of welders. For example, novices are prone to defects such as lack of fusion and slag inclusion.

Typical application areas of SMAW

Buildings and bridges: used for connecting steel structure frames, such as welding of steel beam nodes, to meet the needs of operations in complex spatial locations.

Ships and pressure vessels: In small cabins or containers, SMAW can complete weld repairs that other automatic welding cannot cover.

Field maintenance: For example, when repairing oil pipelines, there is no need to rely on gas protection and strong wind resistance.

Future Development Prospects

Although automated welding technologies (such as robot GMAW and laser welding) are rapidly popularizing in the industrial field, SMAW will still maintain its vitality in the following directions:

(I). Irreplaceable flexibility: In scenarios where automated equipment is difficult to deploy, such as in the wild, at high altitude, and in confined spaces, SMAW is still the preferred process due to its light equipment and the lack of external energy (such as shielding gas).

(II). Process optimization and material innovation: Develop low-smoke coatings and high-efficiency alloy electrodes to increase the deposition rate and reduce pollution. Combine intelligent welding machines (automatically adjust current/voltage) and AR training systems to reduce dependence on welder experience.

(III). Deepen application in subdivided fields:

Nuclear power maintenance: The repair of old nuclear facilities needs to avoid the introduction of electronic interference equipment, and the electromagnetic compatibility advantage of SMAW is highlighted.

Developing country market: In the early stages of industrialization, low-cost and easy-to-maintain SMAW equipment will still dominate the mainstream.

SUMMARY

Manual arc welding has been developed for a hundred years. Although it faces the impact of automation technology, its core value of “simple, reliable, flexible and universal” makes it irreplaceable in specific fields. Especially in small and medium-sized enterprises and developing countries, it still plays an important role. For example, 90% of on-site welding in African infrastructure projects still relies on SMAW because of its low equipment cost and adaptability to harsh environments.

The American Welding Society predicts that by 2030, the global annual demand for SMAW welding rods will remain above 8 million tons, especially in the fields of energy infrastructure and maintenance. As a saying goes “When other welding methods fail, you can always find that reliable welding rod in the tool box.”

Post time: Mar-07-2025