There is no difference in process between full argon arc welding and argon arc welding. Full argon arc welding is suitable for thin-walled small-diameter pipes (generally DN60 and below, wall thickness 4mm), the purpose is to ensure the quality of the weld root and the appearance.

When the diameter of the pipe is large and the wall thickness is thick, argon arc welding should be used as the base and manual welding to cover the surface. The purpose of manual welding is to ensure the appearance quality of large pipe diameter and manual welding, and the work efficiency is higher than that of argon arc welding. lower than argon arc welding.

The argon arc welding bottom welding process is used in the welding of boiler water walls, superheaters, economizers, etc. The quality of the joints is excellent, and the weld grades are above Class II after radiographic inspection.

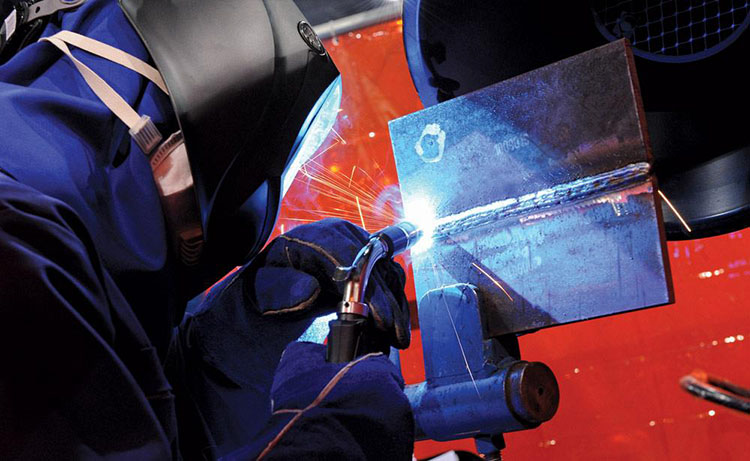

Advantages of argon arc welding

(1) good quality

As long as the appropriate welding wire, welding process parameters and good gas protection are selected, the root can get good penetration, and the penetration is uniform, and the surface is smooth and tidy. There are no defects such as weld bumps, incomplete penetration, depressions, pores and slag inclusions that are easy to occur during arc welding with general electrodes.

(2) High efficiency

In the first layer of welding of the pipeline, manual argon arc welding is continuous arc welding. The electrode arc welding is broken arc welding, so manual argon arc welding can increase the efficiency by 2 to 4 times. Since argon arc welding does not produce welding slag, there is no need to clean up the slag and repair the weld bead, and the speed will increase faster. In the second layer of arc welding cover surface, the smooth and tidy argon arc welding bottom layer is very beneficial to the arc welding cover surface, which can ensure good fusion between layers, especially in the welding of small diameter pipes, the efficiency is more significant.

(3) Easy to master

The welding of the root weld of manual arc welding must be performed by experienced and highly skilled welders. Manual argon arc welding is used for backing, and workers who are generally engaged in welding work can basically master it after a short period of practice.

(4) Small deformation

The heat-affected zone is much smaller during argon arc welding, so the deformation of the welded joint is small and the residual stress is also small.

Process introduction

(1) Welding example

The economizer, evaporator tube bundle, water wall and low-temperature superheater are made of No. 20 steel, and the high-temperature superheater tube is 12Cr1MoV.

(2) Preparation before welding

Before welding, the pipe mouth should be beveled at 30°, and the metal color should be polished within 15mm inside and outside the pipe end. The gap between the pipe counterparts is 1~3mm. When the actual gap is too large, it is necessary to surfacing the transition layer on the side of the pipe groove first. Set up temporary wind shelter facilities and strictly control the wind speed at the welding operation place, because the wind speed exceeds a certain range, and air holes are easily generated.

(3) Operation

Use a manual tungsten argon arc welding machine, the welding machine itself is equipped with a high-frequency arc ignition device, and high-frequency arc ignition can be used. Arc extinguishing is different from electrode arc welding. If the arc is extinguished too quickly, arc crater cracks are easy to occur. Therefore, during operation, the molten pool should be led to the edge or the thicker base metal, and then gradually shrink the molten pool to slowly extinguish the arc, and finally close the arc. Protective gas.

For No. 20 steel pipes with a wall thickness of 3~4mm, the filling material can be TIGJ50 (for 12Cr1MoV, 08CrMoV can be used), the diameter of the tungsten rod is 2mm, the welding current is 75~100A, the arc voltage is 12~14V, and the flow rate of the shielding gas is 8~10L/ min, the type of power supply is DC positive connection.

The reason why argon arc welding can be used so widely is mainly because of the following advantages.

1. Argon protection can isolate the adverse effects of oxygen, nitrogen, hydrogen, etc. in the air on the arc and molten pool, reduce the burning loss of alloy elements, and obtain dense, spatter-free, high-quality welded joints;

2. The arc combustion of argon arc welding is stable, the heat is concentrated, the arc column temperature is high, the welding production efficiency is high, the heat-affected zone is narrow, and the stress, deformation and crack tendency of the welded parts are small;

3. Argon arc welding is open arc welding, which is convenient for operation and observation;

4. The electrode loss is small, the arc length is easy to maintain, and there is no flux or coating layer during welding, so it is easy to realize mechanization and automation;

5. Argon arc welding can weld almost all metals, especially some refractory metals and easily oxidized metals, such as magnesium, titanium, molybdenum, zirconium, aluminum, etc. and their alloys;

6. It is not limited by the position of the weldment, and can be welded in all positions.

The main disadvantages:

1. Due to the large heat-affected area of argon arc welding, the workpiece often causes deformation, high hardness, blisters, local annealing, cracking, pinholes, wear, scratches, undercuts, or insufficient bonding force and internal stress after repairing. defects such as damage. Especially in the process of repairing small defects of investment castings, it is prominent on the surface. In the field of repairing defects of precision castings, cold welding machines can be used instead of argon arc welding. Due to the small heat release of cold welding machines, the shortcomings of argon arc welding are better overcome, and the repairing problems of precision castings are made up for.

2. Argon arc welding is more harmful to the human body than electrode arc welding. The current density of argon arc welding is high, and the light emitted is relatively strong. The ultraviolet radiation generated by its arc is about that of ordinary electrode arc welding. 5 to 30 times, and infrared rays are about 1 to 1.5 times that of electrode arc welding. The ozone content generated during welding is relatively high. Therefore, try to choose a place with good air circulation for construction, otherwise it will cause great harm to the body.

3. For metals with low melting point and easy evaporation (such as lead, tin, zinc), welding is more difficult.

Post time: Aug-16-2023