-

Cast iron is an early used structural material. Many parts of mechanical equipment are made of cast iron. At the same time, the repair welding of cast iron parts is still a common problem. 1 Classification of cast iron and its typical materials Cast iron is an iron-carbon alloy with carbon conten...Read more »

-

In today’s world where welding technology is changing with each passing day, Shielded Metal Arc Welding (SMAW) is still active in the industrial field with its unique vitality. From steel structure welding of skyscrapers to emergency repairs of field oil pipelines, this process, which was b...Read more »

-

Welding material standards are an important basis for ensuring welding quality and safety. Different countries or regions have formulated corresponding standards according to their own industrial needs. The following are several common welding material standards and their characteristics: 1. ISO ...Read more »

-

We promise to strictly control the quality to ensure that every product meet the standard. In the meantime, we arrange production efficiently and deliver on time, so that you can receive the goods with peace of mind and use them with satisfaction. Read more »

-

Flux-cored welding wire first appeared in the United States and Germany in the 1920s. However, it was not until the 1950s that it was really widely used in industrial production, especially after the 1960s and 1970s. With the emergence of fine-diameter (below φ2.0mm) all-position flux-cored weldi...Read more »

-

-

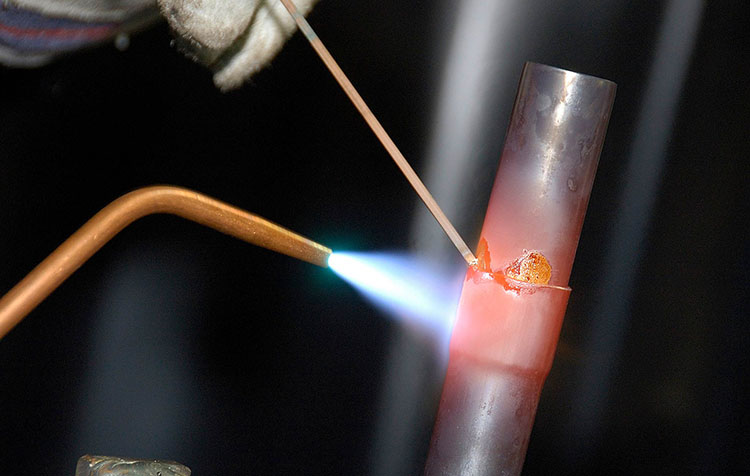

The energy source of brazing can be chemical reaction heat or indirect heat energy. It uses a metal with a melting point lower than that of the material to be welded as the solder. After heating, the solder melts, and the capillary action pushes the solder into the gap between the contact surface...Read more »

-

Harmful factors of welding materials, what should be paid attention to when using welding materials?

Harmful factors of welding materials, what should be paid attention to when using welding materials?Harmful factors of welding materials (1) The main research object of welding labor hygiene is fusion welding, and among them, the labor hygiene problems of open arc welding are the biggest, and the problems of submerged arc welding and electroslag welding are the least. (2) The main harmful fa...Read more »

-

Welding can use AC or DC welding machine. When using a DC welding machine, there are positive connection and reverse connection. Factors such as the electrode used, the condition of the construction equipment, and the welding quality should be considered. Compared with AC power supply, DC power s...Read more »

-

Red head thoriated tungsten electrode (WT20) Currently the most stable and widely used tungsten electrode is mainly used in the welding of carbon steel, stainless steel, silicon copper, copper, bronze, titanium and other materials, but it has slight radioactive pollution. Gray head cerium tungst...Read more »