-

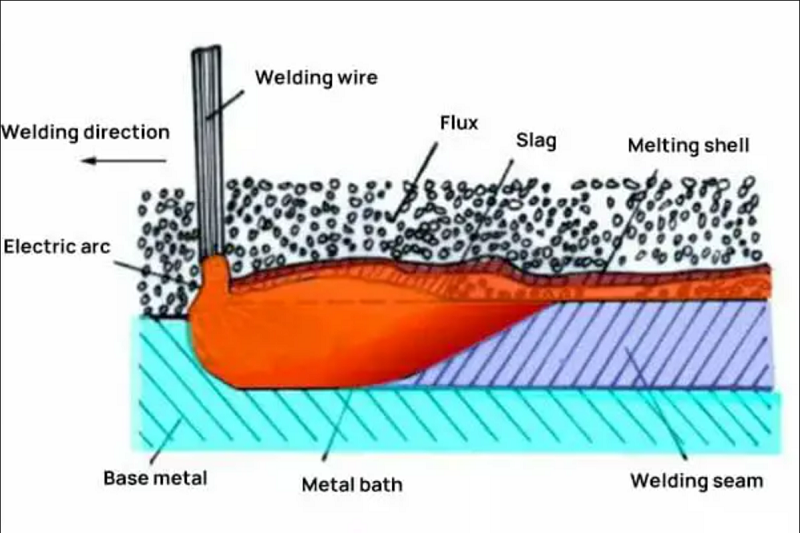

What is flux-cored arc welding? Flux-cored wire arc welding is a welding method that uses the arc between flux-cored wire and workpiece to heat, and its English name is simply FCAW. Under the action of arc heat, welding wire metal and workpiece are connected by melting, forming a weld pool, arc f...Read more »

-

When welding stainless steel, the performance of the electrode must match the purpose of the stainless steel. Stainless steel electrode must be selected according to the base metal and working conditions (including working temperature, contact medium, etc.). Four types of stainless steel as well ...Read more »

-

– FLUX– Flux is a granular welding material. During welding, it can be melted to form slag and gas, which plays a protective and metallurgical role on the molten pool. Constituent Flux is composed of marble, quartz, fluorite and other ores and titanium dioxide, cellulose and oth...Read more »

-

Welding is a process in which the materials of the workpieces to be welded (the same or different) are combined by heating or pressure or both, and with or without filling materials, so that the materials of the workpieces are bonded between atoms to form a connection. So what are the key points...Read more »

-

TIG 1.Application : TIG welding (tungsten argon arc welding) is a welding method in which pure Ar is used as a shielding gas and tungsten electrodes are used as electrodes. TIG welding wire is supplied in straight strips of a certain length (usually lm). Inert gas shielded arc welding using...Read more »

-

Welding work involves many industrial fields, welding fume is one of the most common hazards of welding work. Welding fume is in the welding process when the welding rod and welding parts in contact, in the case of high temperature combustion generated a kind of fume, this fume contains manganese...Read more »

-

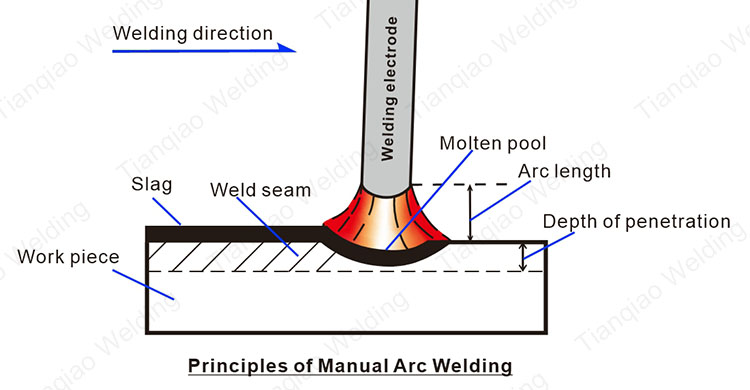

SMAW, also be well known as electrode arc welding, is a fusion welding method in which the arc is induced by the electrode and the welding parts are melted by the arc heat. It is the most widely used and common welding method at present. Arc is an air conduction phenomenon. The welding arc is a ...Read more »

-

Consider the physical properties, mechanical properties and chemical composition of the weld material 1. Structural steel welding, generally consider the principle of equal strength, choose to meet the requirements of the mechanical properties of the joint welding material. 2. For low carbon ...Read more »

-

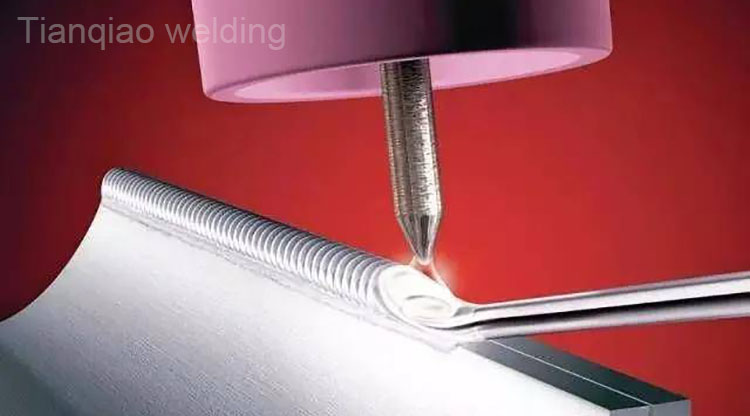

Tungsten argon arc welding is a kind of arc welding method using argon or argon rich gas as protection and tungsten electrode as electrode, which is referred to as GTAW(Gas Tungsten Arc Weld) or TIG(Tungsten Inert Gas Welding) for short. During welding, the shielding gas is continuously sprayed...Read more »

-

The preparation work before welding is as important as the welding process, which is directly related to the welding quality and effect of the finished product. 1. Electrode drying The purpose of drying the electrode before welding is to remove the moisture in the wet electrode and reduce the hy...Read more »