-

The welding electrodes that leave the factory have been dried at high temperature and packaged with moisture-proof material, which usually prevents the coating from absorbing moisture. However, during the long-term storage of the electrode, the moisture absorption of the electrode coating is inev...Read more »

-

The welding parameters of electrode arc welding mainly include electrode diameter, welding current, arc voltage, number of welding layers, power source type and polarity, etc. 1. Selection of electrode diameter The choice of electrode diameter mainly depends on factors such as the thickness of th...Read more »

-

The demand for steel in modern society is constantly increasing. In daily life, many things are made of metal, and many metals cannot be cast at the same time. Therefore, it is necessary to use electric welding for welding. The role of the electrode in the electric welding process is very importa...Read more »

-

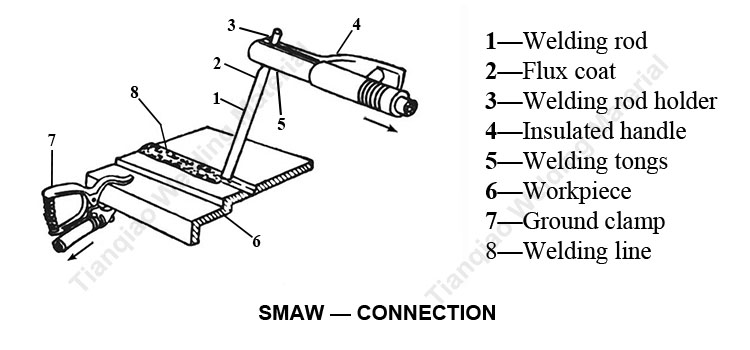

Electrode arc welding is the most widely used welding method in industrial production. The metal to be welded is one pole, and the electrode is the other pole. When the two poles are close to each other, an arc is generated. The heat generated by arc discharge (commonly known as arc combustion) i...Read more »

-

Shielded Metal Arc Welding (abbreviated as SMAW). The principle is: an arc is generated between the coated electrode and the base metal, and the welding method using the arc heat to melt the electrode and the base metal. The outer layer of the electrode is covered with welding flux and melts when...Read more »

-

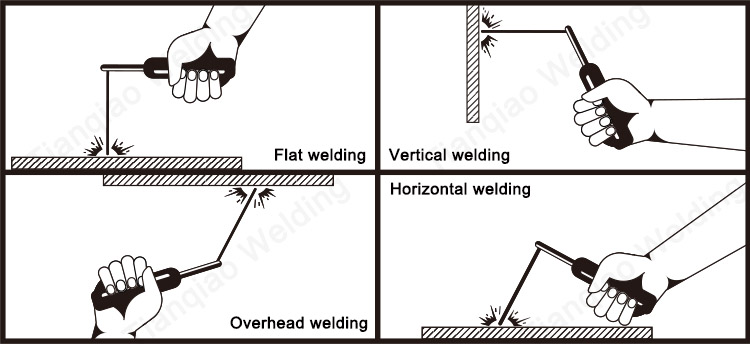

The welding position is referred to when welding, the relative spatial position of the weld to the welder. Figure 1. Tianqiao welding positon There are flat welding, horizontal welding, vertical welding and overhead welding. Flat welding refers to the horizontal welding performed by the welder ...Read more »

-

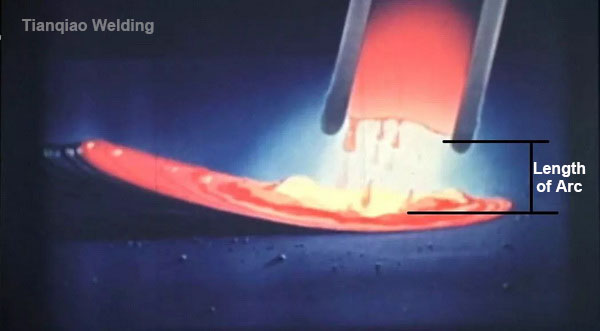

During fusion welding, under the action of the welding heat source, the liquid metal part with a certain geometric shape formed on the weldment by the molten electrode metal and the partially molten base metal is the molten pool. After cooling, it becomes a weld, so the temperature of the molten ...Read more »

-

Selection of welding electrode according to the chemical composition, mechanical properties, anti-cracking performance requirements, at the same time, taking into account the welding structure, steel thickness, working conditions, stress, welding performance and other factors comprehensive analys...Read more »

-

First, Welding cracks and pores are generated. The moisture absorbed by the welding rod becomes gas under the action of the welding arc heat, which decomposes hydrogen, resulting in the formation of welding cracks and pores. This is especially true for alkaline electrodes. The welding rod is sea...Read more »

-

Q1: What is welding material? What to include? Answer: Welding materials include welding rods, welding wires, fluxes, gases, electrodes, gaskets, etc. Q2: What is acid electrode? Answer: The coating of the acid electrode contains a large amount of acid oxides such as SiO2, TiO2 and a cert...Read more »