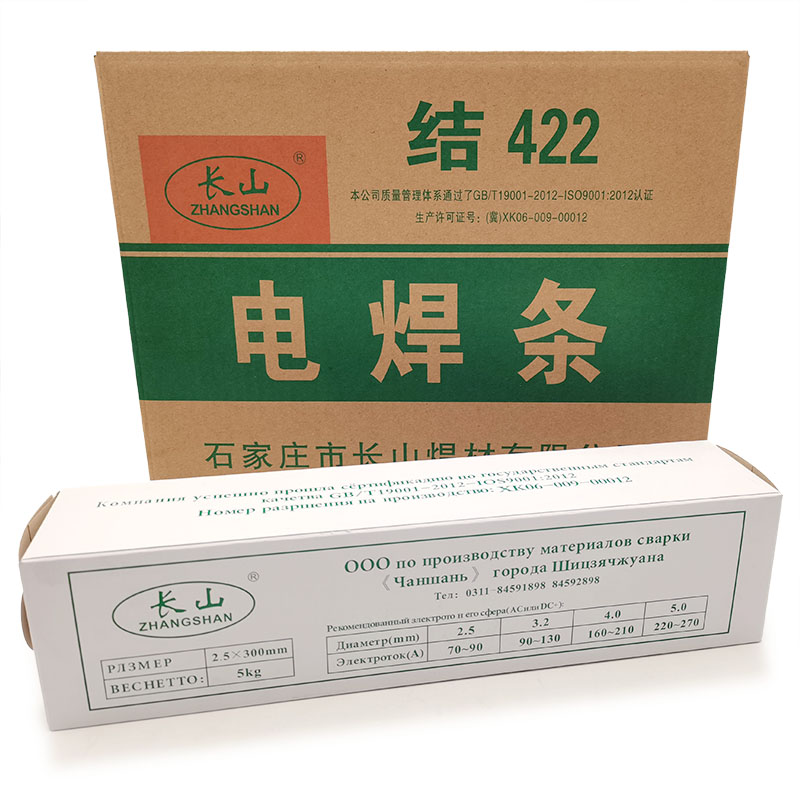

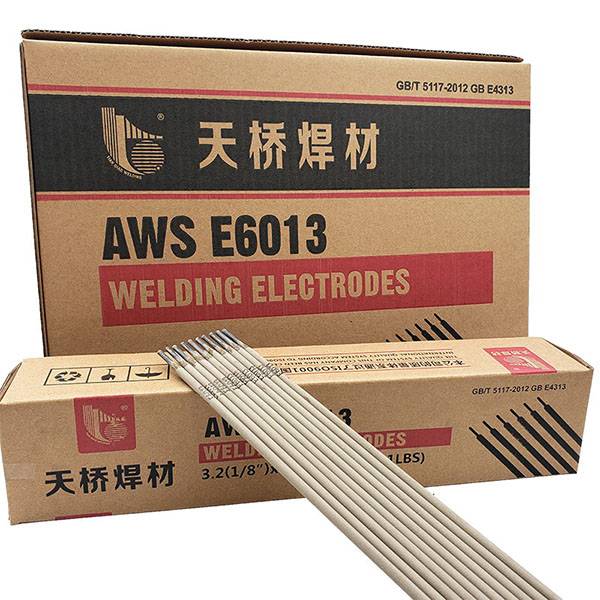

OEM/ODM Factory China Brand 2.5mm 3.2mm 4.0mm Carbon Steel Welding Electrodes Esab J422 J421 Aws E6013

We are proud in the significant client satisfaction and wide acceptance due to our persistent pursuit of top quality both on merchandise and repair for OEM/ODM Factory China Brand 2.5mm 3.2mm 4.0mm Carbon Steel Welding Electrodes Esab J422 J421 Aws E6013, We sincerely expect exchange and cooperation along with you. Let us move forward hand in hand and accomplish win-win situation.

We are proud in the significant client satisfaction and wide acceptance due to our persistent pursuit of top quality both on merchandise and repair for China Welding Electrode, welding rod, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we’ll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

APPLICATIONS:

Used for welding important low-carbon steel structures and low-alloy steel structures with low strength grades, such as Q235, 09MnV, 09Mn2, and etc.

CHARACTERISTICS:

J422 is a rutile type electrode. Can be welding by both AC & DC power source and can be for all-position. It have excellent welding performance as stable arc, little spatter, easy slag removal and reignition-ability etc.

ATTENTION:

In generally, don’t need to re-dry the electrode before welding. When it be affected with damp, should be re-dry it at 150℃-170℃ for 0.5-1 hour.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

X-ray flaw detection: Ⅱ level

DEPOSIT COMPOSITION (Quality Score): %

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requirements |

≤0.10 |

0.32-0.55 |

≤0.30 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typical Results |

0.08 |

0.37 |

0.14 |

0.018 |

0.022 |

0.030 |

0.035 |

0.005 |

0.004 |

MECHANICAL PROPERTIES:

|

Items |

Tensile Strength Rm/MPa |

Yield Strength Rel/Rp0.2 MPa |

Elongation A/% |

Charpy V-Notch KV2(J)0℃ |

|

Requirements |

430-560 |

≥330 |

≥22 |

≥47 |

|

Typical Results |

480 |

420 |

28 |

80 |

TYPICAL OPERATING PROCEDURES: (AC,DC)

|

Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

|

Current (A) |

40-70 |

60-90 |

90-140 |

160-210 |

220-270 |

PACKAGING:

5kgs/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21-26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging according to your design, please contact us for detail discussion.

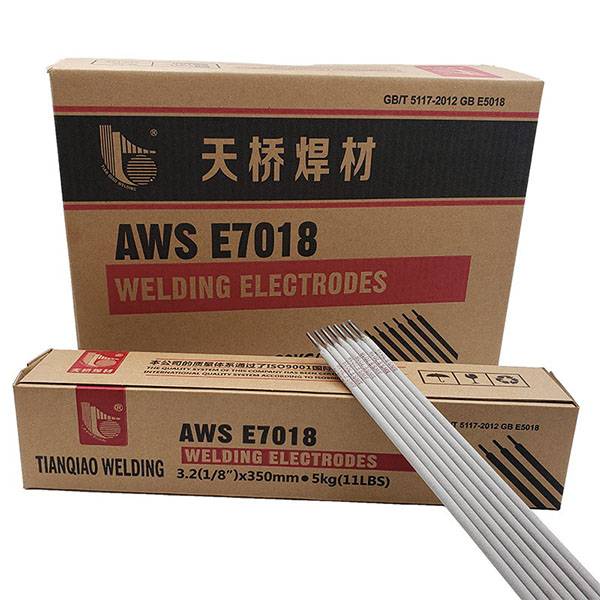

Shijiazhuang Tianqiao Welding Materials Co., Ltd was founded in 2007. As professional welding electrode manufacturer, we have strong technical force, complete product testing equipment so that we can keep stable product quality. Our products include kinds of welding electrodes with the brand of “Yuanqiao”, “Changshan”, such as low carbon steel, Iow alIoy steel, heat-resistant steels, low temperature steel, stainless steel, cast iron, hard surfacing welding electrodes and various mixed welding powder.

The products are widely used in various national economic fields, such as machinery, metallurgy, petroleum chemical industry, boiler, pressure vessel, the ships, the buildings, s, and so on, The products are sold to all over the country, and well received by the vast users. Our products have excellent performance, stable quality, elegant welding molding, and good slag removal, good ability to resist rust, Stomata and crack, good and stable deposited metal mechanics performance. Our products are one hundred percent exported and have sold world widely, mainly to US, Europe, South America, Australia, Africa, Middle East, Southeast Asia and etc. Our products meet customers’ warm welcome due to the excellent quality, outstanding performance and competitive price.

APPLICATIONS:

Used for welding important low-carbon steel structures and low-alloy steel structures with low strength grades, such as Q235, 09MnV, 09Mn2, and etc.

CHARACTERISTICS:

J422 is a rutile type electrode. Can be welding by both AC & DC power source and can be for all-position. It have excellent welding performance as stable arc, little spatter, easy slag removal and reignition-ability etc.

ATTENTION:

In generally, don’t need to re-dry the electrode before welding. When it be affected with damp, should be re-dry it at 150℃-170℃ for 0.5-1 hour.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

X-ray flaw detection: Ⅱ level

DEPOSIT COMPOSITION (Quality Score): %

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requirements |

≤0.10 |

0.32-0.55 |

≤0.30 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typical Results |

0.08 |

0.37 |

0.14 |

0.018 |

0.022 |

0.030 |

0.035 |

0.005 |

0.004 |

MECHANICAL PROPERTIES:

|

Items |

Tensile Strength Rm/MPa |

Yield Strength Rel/Rp0.2 MPa |

Elongation A/% |

Charpy V-Notch KV2(J)0℃ |

|

Requirements |

430-560 |

≥330 |

≥22 |

≥47 |

|

Typical Results |

480 |

420 |

28 |

80 |

TYPICAL OPERATING PROCEDURES: (AC,DC)

|

Diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

|

Current (A) |

40-70 |

60-90 |

90-140 |

160-210 |

220-270 |

PACKAGING:

5kgs/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21-26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging according to your design, please contact us for detail discussion.

Shijiazhuang Tianqiao Welding Materials Co., Ltd was founded in 2007. As professional welding electrode manufacturer, we have strong technical force, complete product testing equipment so that we can keep stable product quality. Our products include kinds of welding electrodes with the brand of “Yuanqiao”, “Changshan”, such as low carbon steel, Iow alIoy steel, heat-resistant steels, low temperature steel, stainless steel, cast iron, hard surfacing welding electrodes and various mixed welding powder.

The products are widely used in various national economic fields, such as machinery, metallurgy, petroleum chemical industry, boiler, pressure vessel, the ships, the buildings, s, and so on, The products are sold to all over the country, and well received by the vast users. Our products have excellent performance, stable quality, elegant welding molding, and good slag removal, good ability to resist rust, Stomata and crack, good and stable deposited metal mechanics performance. Our products are one hundred percent exported and have sold world widely, mainly to US, Europe, South America, Australia, Africa, Middle East, Southeast Asia and etc. Our products meet customers’ warm welcome due to the excellent quality, outstanding performance and competitive price.

We are proud in the significant client satisfaction and wide acceptance due to our persistent pursuit of top quality both on merchandise and repair for OEM/ODM Factory China Brand 2.5mm 3.2mm 4.0mm Carbon Steel Welding Electrodes Esab J422 J421 Aws E6013, We sincerely expect exchange and cooperation along with you. Let us move forward hand in hand and accomplish win-win situation.

OEM/ODM Factory China Welding Electrode, Welding Rod, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we’ll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.