Original Factory Stainless Steel Filler Rod - Z408 Pure Nickel Cast Iron Electrode AWS ENiFe-CI – Tianqiao

Original Factory Stainless Steel Filler Rod - Z408 Pure Nickel Cast Iron Electrode AWS ENiFe-CI – Tianqiao Detail:

APPLICATIONS:

It is suitable for the welding of high-strength gray iron and nodular cast iron, such as cylinder, engine block, gear box,etc..

CHARACTERISTICS:

Z408 is the cast iron electrode with nickel iron alloy core and strong reduction of graphite coating . It can be used in AC and DC dual purpose, has stable arc,and is easy to operate. The electrode has the characteristics of high strength, good plasticity, low linear expansion coefficient and so on. The crack resistance for grey cast iron is as much as that for Z308, while the crack resistance for nodular cast iron is more than Z308. For cast iron with higher phosphorus (0.2%P), it also has a good results and its tocutting performance is lower than Z308 andZ508 slightly. Z408 is used in the welding of gray iron and nodular cast iron for room

ATTENTION:

Before welding, the electrodes need to be baked for 1 hour with the temperature of 150±10℃ before using.

When welding ,it is appropriate to take narrow weld and each weld length should not exceed 50mm. Hammer the welding area lightly with a hammer immediately after welding in order to eliminate stress and prevent cracks.

Lower heat input is recommend.

Chemical Composition of the deposited metal(the mass fraction): %

|

Elements |

C |

Si |

Mn |

S |

Fe |

Ni |

Cu |

The mass of other elements |

|

Standard value |

0.35-0.55 |

≤0.75 |

≤ 2.3 |

≤0.025 |

3.0- 6.0 |

60- 70 |

25- 35 |

≤ 1.0 |

Welding reference current:(AC,DC+)

|

Electrode diameter(mm) |

3.2 |

4.0 |

5.0 |

|

Length (mm) |

350 |

350 |

350 |

|

Welding current(A) |

90-110 |

120-150 |

160-190 |

FAQ:

1.Hot specifications:

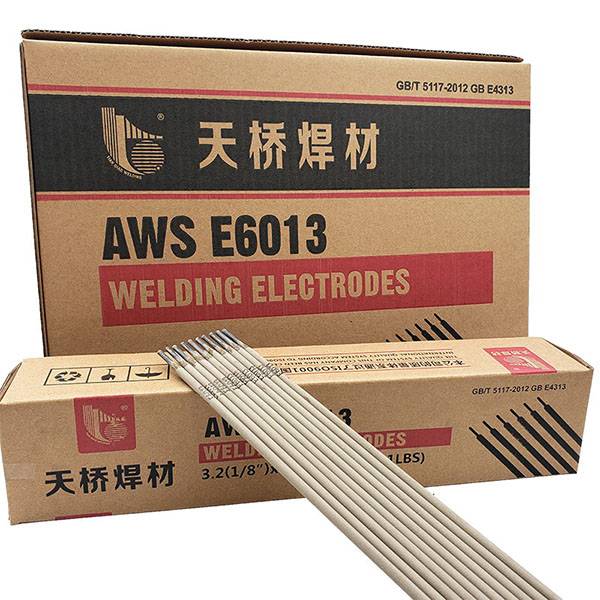

E6013, E6011, E6010, E7018, S.S. E308, E309, E310, E316

2.OEM design:

Yes, we can print your logo on the welding electrode; also make your brand packing box.

3.Free samples?

Yes, if you need 1 or 2 kgs. But the freight cost is paid by yourside.

4.Certifications:

ISO, SGS, our registered brand “ TIANQIAO” “YUANQIAO”, etc.

5.Delivery time?

10-15 days after we received your deposit.

6. MOQ?

One full 20ft container, that is 25tons.

7.Payment term?

30% T/T in advance and balance before loading container.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Sincerity, Innovation, Rigorousness, and Efficiency will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Original Factory Stainless Steel Filler Rod - Z408 Pure Nickel Cast Iron Electrode AWS ENiFe-CI – Tianqiao, The product will supply to all over the world, such as: St. Petersburg, Guyana, Macedonia, Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.