Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao

Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao Detail:

Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40

Low fuming bronze RBCuZn-A Brass Gas Welding Rods

Chemical Composition ( % ):

| Standard | Class | Alloy | Cu | Al | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Other |

| ISO24373 | Cu4700 | CuZn40Sn | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

| GB/T9460 | SCu4700 | CuZn40Sn | 57.0-61.0 | Max 0.01 | - | - | - | - | Max 0.05 | - | 0.25-1.0 | bal | Max 0.5 |

| BS EN14640 | Cu4700 | CuZn40 | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

| AWS A5.8 | C47000 | RBCuZn-A | 57.0-61.0 | 0.01 | - | - | - | - | 0.05 | - | 0.25-1.0 | bal | 0.5 |

Physical Properties and Mechanical Properties:

|

Solids-Temperature |

886°C |

Liquids-Temperature |

901°C |

|

|

Density |

8.45kg/dm3 |

Tensile Strength |

375N/mm2 |

|

|

Elongation |

35% |

Brinell Hardness |

85HB |

Applications

Most popular for padding material of gas-welding and carbon are welding in brass. Can also used in brazing of copper, steel, copper-nickel, cast iron and carbide cutting alloy tools incrustation.

Chemical Composition ( % ):

| Standard | Class | Alloy | Cu | Al | Fe | Mn | Ni | P | Pb | Si | Sn | Zn | Other |

| ISO24373 | Cu4641 | CuZn40SnSi | 58.0-62.0 | 0.01 | 0.2 | 0.3 | - | - | 0.03 | 0.1-0.5 | 1.0 | bal | 0.2 |

| GB/T9460 | SCu6810A | CuZn40SnSi | 58.0-62.0 | Max 0.1 | Max 0.2 | Max 0.3 | - | - | Max 0.03 | 0.1-0.5 | Max 1.0 | bal | Max 0.2 |

| BS EN14640 | SCu6810 | CuZn40SnSi | 58.0-62.0 | 0.01 | 0.2 | 0.3 | - | - | 0.03 | 0.1-0.5 | 1.0 | bal | 0.2 |

| DIN 1733 | 2.0366 | SG-CuZn40Si | 58.0-62.0 | Max 0.01 | Max 0.2 | Max 0.3 | - | - | Max 0.03 | 0.1-0.5 | Max 1.0 | bal | Max 0.2 |

Physical Properties and Mechanical Properties:

|

Solids-Temperature |

870-890°C |

Liquids-Temperature |

880-910°C |

|

|

Density |

8.4kg/dm3 |

Tensile Strength |

381N/mm2 |

|

|

Elongation |

30% |

Brinell Hardness |

88HB |

Advantages:

1.Good wear resistance of Brass Gas Welding Rods.

2.Excellent corrosion resistance;

3.High intensity.

4.Suface clean, Good smooth

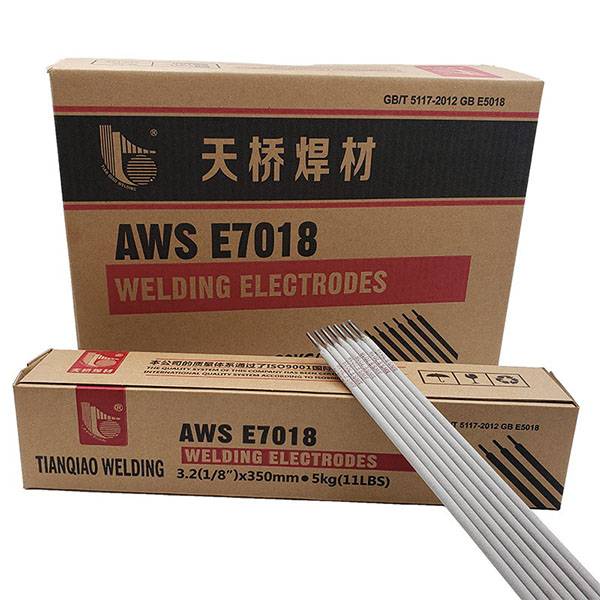

Package details:

- 5kg or 10kg/shrink film; 500kgs/wooden case

- As per your requirement

Business term: CIF, CNF, FOB

OEM is acceptable; and free samples.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for Popular Design for 3.2 Mm Welding Rods Amps - Brass Gas Welding Rods Brass brazing rod HS221 Brazing alloy HS221 CuZn40 – Tianqiao, The product will supply to all over the world, such as: India, Ottawa, Lisbon, The credibility is the priority, and the service is the vitality. We promise we have now the ability to offer excellent quality and reasonable price items for customers. With us, your safety is guaranteed.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.