professional factory for 6012 Welding Rod - Stainless Steel Welding Electrode AWS E316-16 (A202) – Tianqiao

professional factory for 6012 Welding Rod - Stainless Steel Welding Electrode AWS E316-16 (A202) – Tianqiao Detail:

APPLICATIONS:

It is suitable for welding 06Cr17Ni12Mo2 stainless steel equipment working in organic and inorganic acid (non-oxidizing acid) medium. It can also be used for welding high chromium steels or dissimilar steels that cannot be heat-treated after welding.

CHARACTERISTICS:

E316-16 is a Cr18Ni12Mo2 stainless steel electrode with rutile coating. Both AC and DC can be used for all-position welding. It has excellent welding performance. Deposited metal has good corrosion resistance, heat resistance and crack resistance, especially against chloride ion pitting corrosion.

ATTENTION:

1. Before welding, the electrode shall be baked at 320-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. Dc power supply is recommended, because the depth of current welding is relatively shallow, the current should not be too large, so as to avoid redness and cracking of the skin.

4. Reduce the heat input as much as possible, and the swing amplitude of the electrode should not be too large.

5. Preheat and keep the temperature between channels below 150℃.

WELDING POSITIONS:

PA, PB, PD, PF

CHEMICAL COMPOSITION OF ALL WELDING METAL: (Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

Cu |

|

Requirements |

≤0.08 |

0.5-2.5 |

≤1.0 |

≤0.03 |

≤0.04 |

11.0-14.0 |

17.0-20.0 |

2.0-2.5 |

≤0.75 |

|

Typical Results |

0.04 |

0.96 |

0.68 |

0.010 |

0.028 |

11.65 |

19.0 |

2.41 |

0.08 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

A/% |

| Requirements |

≥520 |

≥25 |

| Typical Results |

595 |

42 |

TYPICAL OPERATING PROCEDURES: (AC or DC+)

| Diameter (mm) |

2.5 |

3.2 |

4.0 |

5.0 |

| Length (mm) |

300 |

350 |

400 |

400 |

| Current (A) |

50-80 |

80-110 |

110-160 |

160-200 |

PACKAGING:

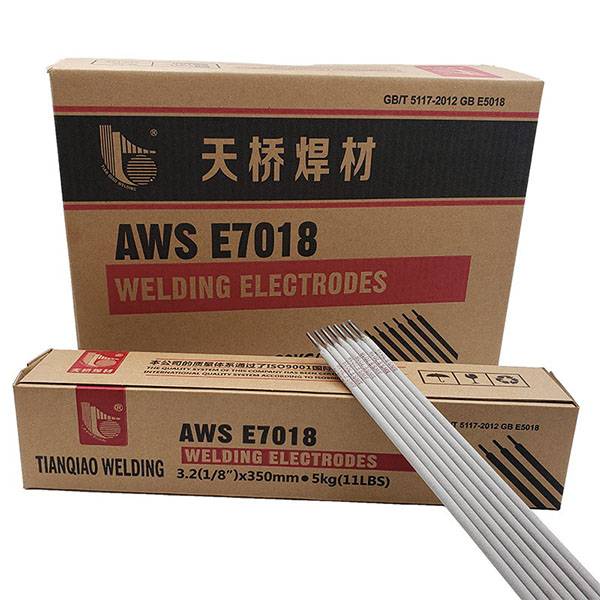

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging accord to your design, please contact us for detail discussion.

Our company has a strong technical force, reliable production technology, advanced production equipment, perfect testing methods, standardized management mechanism, and a high-quality workforce, which ensure the continuous improvement of production capacity and product quality. We have a complete sales team and have been committed to providing customers with efficient product supply support. Our company’s welding rod products have won the recognition and trust of customers with excellent quality, good reputation and sound service system.

For many years, our company has always adhered to the business strategy of “good welding rod, made with conscience”. Encouraged by the spirit of “high efficiency, low consumption, collaboration and innovation”, all employees are guided by the policy of “not for the best, but for the better”. Next, with the goal of creating a “famous brand”, we will use modern and cutting-edge management models to standardize the company, and strive to build the best and most advanced corporate culture that is compatible with the company, so that the company will become stronger first and then bigger. .

Exceeding quality is the eternal pursuit of “Tianqiao” welding consumables, so that customers of Tianqiao welding consumables can truly obtain assured products and value-for-money enjoyment.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We emphasize progress and introduce new solutions into the market each year for professional factory for 6012 Welding Rod - Stainless Steel Welding Electrode AWS E316-16 (A202) – Tianqiao, The product will supply to all over the world, such as: Liverpool, Kazakhstan, Georgia, Our organization. Situated inside the national civilized cities, the visitors is very easy, unique geographical and economic situations. We pursue a people-oriented, meticulous manufacturing, brainstorm, construct brilliant organization. hilosophy. Strict top quality management, fantastic service, reasonable cost in Myanmar is our stand on the premise of competition. If vital, welcome to make contact with us by our web page or telephone consultation, we are going to be pleased to serve you.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.