Quality Inspection for 1.6 Mm Welding Electrodes - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao

Quality Inspection for 1.6 Mm Welding Electrodes - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao Detail:

APPLICATIONS:

It is used for cladding shafts and valves of carbon steel or alloy steel whose surfacing temperature is below 450 °C.

CHARACTERISTICS:

D507 is a surfacing electrode with low hydrogen sodium coating.

The surfacing metal is 1Cr13 semi ferrite high chromium steel.

The hardfacing layer has the characteristics of air quenching, generally does not need heat treatment,

and its hardness is uniform, and it can also be annealing-softing in the range of 750°C -800°C .

Dual purpose, good welding process. Heated to 900-1000°C, it can be re hardened after air cooling or oil quenching.

DC reverse connection is available.

WELDING POSITIONS: PA, PB

DEPOSIT COMPOSITION (QUALITY SCORE): %

| items | C | Mn | Si | P | S | Cr | Mo |

| Requirements | 0.12 | - | - | 0.024 | 0.008 | 13.47 | - |

HRC: 41

Product detail pictures:

Related Product Guide:

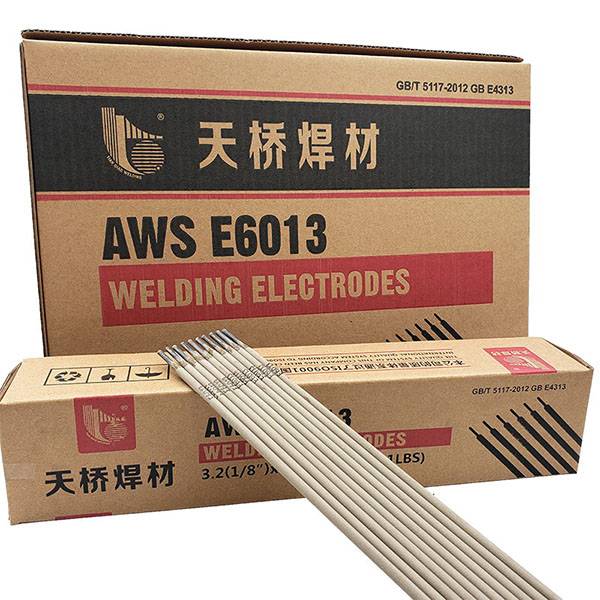

The composition of the welding electrode

We have now a specialist, efficiency staff to provide good quality company for our consumer. We normally follow the tenet of customer-oriented, details-focused for Quality Inspection for 1.6 Mm Welding Electrodes - Valve and shaft Surfacing Welding Electrodes D507 – Tianqiao, The product will supply to all over the world, such as: Muscat, Sri Lanka, Sacramento, Our advantages are our innovation, flexibility and reliability which have been built during last 20 years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. The continual availability of high grade products in combination with our excellent pre- and after-sales service ensures strong competitiveness in an increasingly globalized market.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Send your message to us:

Write your message here and send it to us