Quality Inspection for Welding Rod 7016 - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao

Quality Inspection for Welding Rod 7016 - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao Detail:

High manganese steel surfacing electrode D256 AWS: EFeMn-A

APPLICATIONS:

It is suitable for surfacing welding of various crusher, high manganese rail, bucket, bulldozer, etc.

CHARACTERISTICS:

THD256 is the surfacing electrode of high manganese steel with low hydrogen potassium coating.Can be both ac and dc (ac welding, no-load voltage is not lower than 70V), surfacing welding should use small current, narrow welding, while the red heat immediately hammer or water quenching, in order to reduce the crack tendency.The surfacing metal is austenitic high manganese steel, which has the characteristics of working hardening, toughness and wear resistance.

ATTENTION:

1. Before welding, the electrode shall be baked at 300-350℃ for 1 hour before use.

2. For surfacing welding of worn parts of high manganese steel, the fatigue layer shall be removed or treated with water toughness or soldered with chromium manganese steel electrode (such as D277).

3. Due to the large yellow smoke during surfacing welding, attention should be paid to strengthen ventilation and operate in the windswept position.

WELDING POSITIONS: PA, PB, PC, PD, PE, PF

DEPOSIT COMPOSITION (QUALITY SCORE): %

| Items | C | Mn | Si | Others |

| Requirements | ≤1.10 | 11.00-16.00 | ≤1.30 | ≤5.00 |

TYPICAL OPERATING PROCEDURES: (AC,DC)

| Diameter (mm) | 3.2 | 4.0 | 5.0 |

| Current (A) | 70-90 | 100-140 | 150-180 |

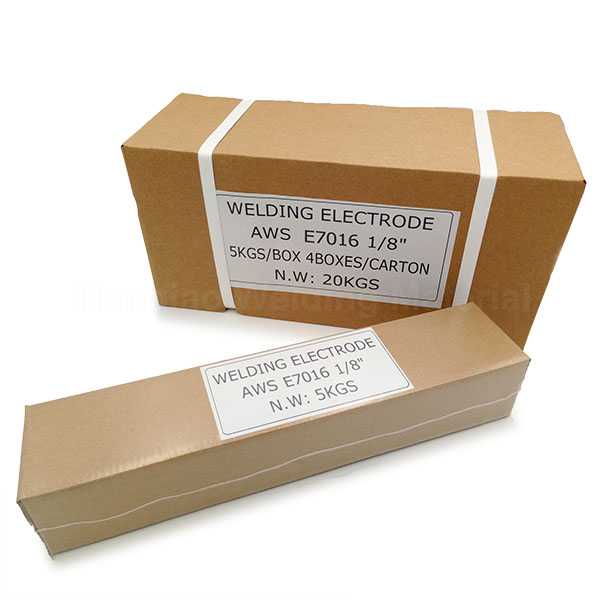

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

We're also concentrating on improving the things administration and QC program to ensure we could maintain terrific gain from the fiercely-competitive company for Quality Inspection for Welding Rod 7016 - High manganese steel surfacing electrode D256 AWS: EFeMn-A – Tianqiao, The product will supply to all over the world, such as: UAE, Pretoria, Amman, Each product is carefully made, it will make you satisfied. Our products in the production process have got strictly monitored, because it is only to provide you the best quality, we will feel confident. High production costs but low prices for our long-term cooperation. You can have a variety choices and the value of all types are same reliable. If you have any question, do not hesitate to ask us.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.