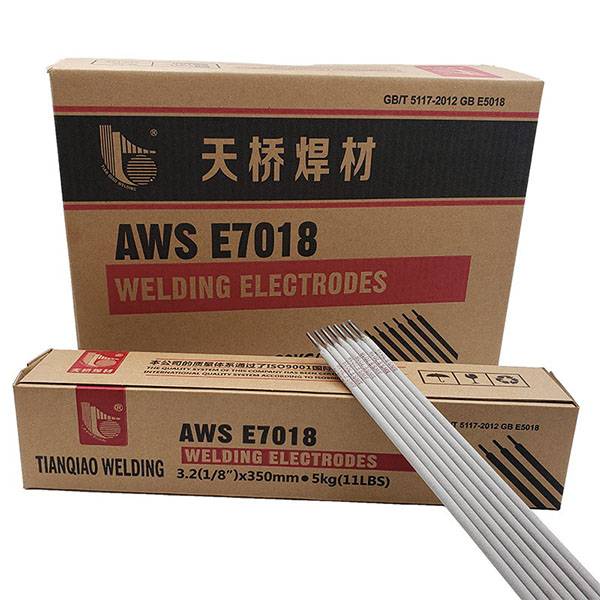

Quality Inspection for Welding Rod 7016 - Mild Steel Welding Electrode AWS E7018 – Tianqiao

Quality Inspection for Welding Rod 7016 - Mild Steel Welding Electrode AWS E7018 – Tianqiao Detail:

APPLICATIONS:

It is suitable for the welding of carbon steel and low alloy steel structure, such as Q345, an so on.

FEATURES:

E7018 is basic coated iron powder low potassium hydrogen type electrode. Both AC and DC can be used and can be all-position welding. It can reach excellent welding performance, good arc stiffness, little spatter, easy slag removal and good weld appearance, high deposition efficiency, and can reduce welding layers.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

X-ray flaw detection: Ⅰ level

DEPOSIT COMPOSITION (Quality Score): %

|

items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

V |

|

Requirements |

≤0.10 |

0.85- 1.40 |

≤0.65 |

≤0.030 |

≤0.035 |

≤0.30 |

≤0.20 |

≤0.30 |

≤0.08 |

|

Typicl Results |

0.06 |

1.00 |

0.30 |

0.015 |

0.020 |

0.030 |

0.035 |

0.005 |

0.004 |

MECHANICAL PROPERTIES:

|

items |

Tensile Strength Rm/MPa |

Yield Strength Rel/Rp0.2 MPa |

Elongation A/% |

Charpy V-Notch KV2(J)-30℃ |

|

Requirements |

490-660 |

≥400 |

≥22 |

≥80 |

|

Typical Results |

590 |

480 |

28 |

160 |

TYPICAL OPERATING PROCEDURES: (AC,DC+)

|

Diameter in(mm) |

2.5 |

3.2 |

4.0 |

5.0 |

|

Current in(A) |

60-100 |

100-150 |

170-210 |

210-250 |

ATTENTION:

1. Electrode must be approved by 350-380℃ for 1 hour before welding, dry the electrode when use it.

2. The rust, oil, water and other impurities of the weld must be removed before welding.

3. Must use short arc welding, the swings should not be too large, narrow bead welding is appropriate.

4. To prevent producing arc porosity, arc plate should be adopted or use return method for arc welding.

PACKAGING:

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

OEM/ODM:

We support OEM/ODM and could make packaging according to your design, please contact us for detail discussion.

Shijiazhuang Tianqiao Welding Materials Co., Ltd was founded in 2007. As professional welding electrode manufacturer, we have strong technical force, complete product testing equipment so that we can keep stable product quality. Our products include kinds of welding electrodes with the brand of “Yuanqiao”, “Changshan”, such as low carbon steel, Iow alIoy steel, heat-resistant steels, low temperature steel, stainless steel, cast iron, hard surfacing welding electrodes and various mixed welding powder.

The products are widely used in various national economic fields, such as machinery, metallurgy, petroleum chemical industry, boiler, pressure vessel, the ships, the buildings, s, and so on, The products are sold to all over the country, and well received by the vast users. Our products have excellent performance, stable quality, elegant welding molding, and good slag removal, good ability to resist rust, Stomata and crack, good and stable deposited metal mechanics performance. Our products are one hundred percent exported and have sold world widely, mainly to US, Europe, South America, Australia, Africa, Middle East, Southeast Asia and etc. Our products meet customers’ warm welcome due to the excellent quality, outstanding performance and competitive price.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

With advanced technologies and facilities, strict quality control, reasonable price, superior service and close co-operation with customers, we are devoted to providing the best value for our customers for Quality Inspection for Welding Rod 7016 - Mild Steel Welding Electrode AWS E7018 – Tianqiao, The product will supply to all over the world, such as: Malta, Egypt, Vancouver, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!