Special Design for 1.5 Mm Welding Rods - Stainless Steel Welding Electrode AWS E312-16 – Tianqiao

Special Design for 1.5 Mm Welding Rods - Stainless Steel Welding Electrode AWS E312-16 – Tianqiao Detail:

APPLICATIONS:

Used for welding high carbon steel, tool steel and dissimilar metals

CHARACTERISTICS:

E312-16 is a duplex stainless steel electrode with a titanium-calcium coating. The welding process performance is excellent, and it can be used for both AC and DC. Because the weld contains about 40% of ferrite, it has excellent crack resistance

ATTENTION:

1. Before welding, the electrode shall be baked at 300-350℃ for 1 hour and used as needed.

2. Remove rust, grease, moisture and other impurities before welding.

3. For welding hardenable steel, when using small current to weld complex and thick workpieces, the workpieces should be preheated at 150℃.

WELDING POSITIONS:

PA, PB, PC, PD, PE, PF

Chemical Composition Of All Welding Metal: (Wt. %)

|

Items |

C |

Mn |

Si |

S |

P |

Ni |

Cr |

Mo |

Cu |

|

Requirements |

0.15 |

0.5-2.5 |

≤1.0 |

≤0.03 |

≤0.04 |

8.0-10.5 |

28.0-32.0 |

≤0.75 |

≤0.75 |

|

Typical Results |

0.09 |

1.08 |

0.76 |

0.010 |

0.028 |

9.97 |

29.0 |

0.12 |

0.17 |

MECHANICAL PROPERTIES OF ALL WELD METAL:

|

Items |

Rm/MPa |

A/% |

| Requirements |

≥660 |

≥15 |

| Typical Results |

760 |

28 |

TYPICAL OPERATING PROCEDURES: (AC or DC+)

| Diameter (mm) |

2.5 |

3.2 |

4.0 |

5.0 |

| Length (mm) |

300 |

350 |

400 |

400 |

| Current (A) |

50-80 |

80-110 |

130-160 |

160-200 |

PACKAGING:

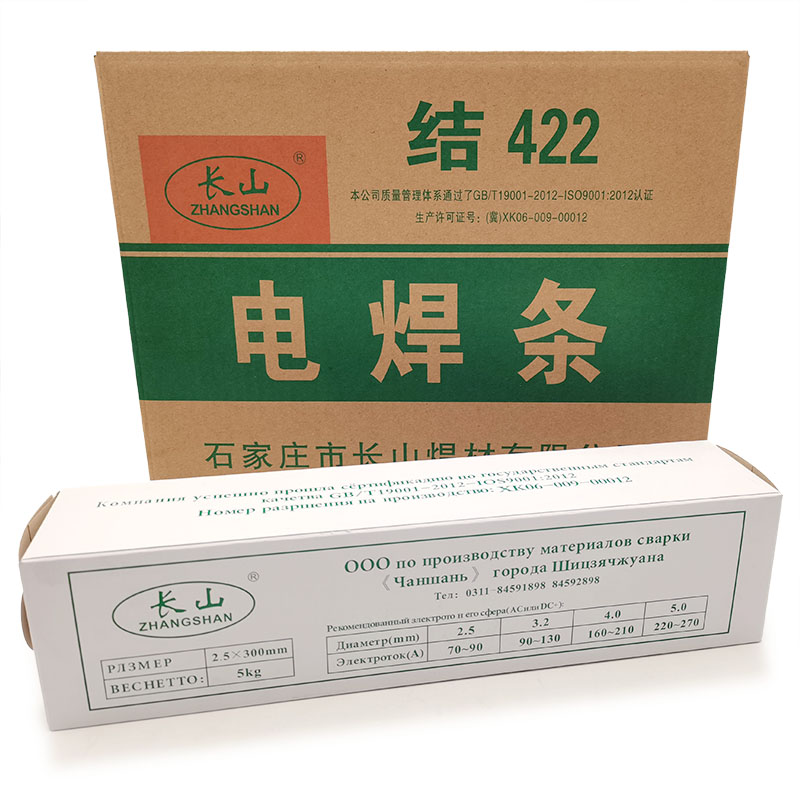

5kg/box, 4boxes/carton, 20kgs/carton, 50cartons/pallet. 21MT -26MT per 1X20″ FCL.

Material requirements for welding parts:

The steel numbers, specifications and ordering requirements of the raw materials of the welding parts shall comply with the requirements of the drawings or technical documents, and the material substitution system shall be strictly implemented for the substitution of materials.

The materials of the welding parts (steel plate, steel, welding rod, welding wire, flux and shielding gas, etc.) shall be inspected and accepted according to the relevant material standards when entering the factory. Materials that cannot be confirmed or have no certificate of conformity must be re-inspected. Can be used.

When selecting welding rods, wires, fluxes and shielding gases for welding parts, it should be based on the principle of equal strength between the weld metal and the base metal to ensure that the weld metal is not lower than the mechanical properties of the base metal, and should comply with the standard GB/ T 5117, GB/T 5118 and GB/T 8110.

Welding rods and fluxes with special instructions should be dried in accordance with the requirements of the instruction manual. The drying temperature without special requirements should meet the requirements of the table. Store it in an incubator after drying, and take it out when you need it. The welding rod should not be baked more than twice. The welding wire must be cleaned of oil and water before use.

Product detail pictures:

Related Product Guide:

The composition of the welding electrode

Based on domestic market and expand overseas business is our development strategy for Special Design for 1.5 Mm Welding Rods - Stainless Steel Welding Electrode AWS E312-16 – Tianqiao, The product will supply to all over the world, such as: Monaco, Israel, Holland, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. Dedicated to providing reliable customer service is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.