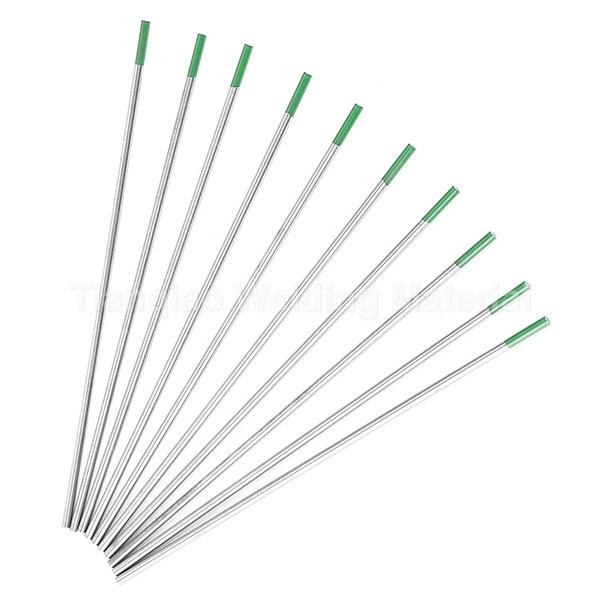

Pure tungsten electrode is the earliest electrode used in TIG welding. It has the characteristics of low resistance, good conductivity and low thermal expansion, and is widely used in various specific welding industries. The pure tungsten electrode contains 99.5% lower tungsten and has no alloying elements. The pure tungsten electrode is only used as a welding electrode under AC conditions or as a resistance welding electrode. It can provide a clean base material surface, and the solder ball becomes sharp when heated. This shape provides a balanced waveform AC welding arc stability, which is particularly good. Pure tungsten has a very high electron escape function, low vapor pressure, low electrical resistance, good electrical conductivity, low thermal expansion, and high elasticity. Therefore, the arc is stable at low current, and aluminum, magnesium and their alloys can be welded well below 5A. However, the emission of electrons requires a higher voltage, and the welding machine requires a high no-load voltage. The tungsten electrode burns out when working with large currents for a long time. Obviously, the end will melt and fall into the molten pool will cause the seam to clamp tungsten, so it is only used for welding some ferrous metals, or welding unimportant parts.

Our tungsten electrode adopts the domestic advanced centerless grinder technology, and the surface of the product has a high degree of smoothness and no burrs. Compared with other products, the arc is more concentrated and more stable.

Features:

1. The pure tungsten electrode contains at least 99.5% tungsten, which has excellent conductivity and durability.

2. Non-radioactive tungsten electrode, no pollution.

3. Low burnout rate and good arc stability.

4. Provide 9 specifications of pure tungsten electrodes to meet your different needs.

5. Mainly used for AC welding of nickel alloy, magnesium aluminum and its alloys.

Model: WP

Material: Tungsten

Classification: ANSI/AWS A5.12M-98 ISO 6848

Packing: 10pc/box

Welding current: please refer to the table below

Nib color: green

Optional size:

| 1.0 * 150mm / 0.04 * 5.91 inches |

1.0 * 175mm / 0.04 * 6.89 inches |

| 1.6 * 150mm / 0.06 * 5.91 inches |

1.6 * 175mm / 0.06 * 6.89 inches |

| 2.0 * 150mm / 0.08 * 5.91 inches |

2.0 * 175mm / 0.08 * 6.89 inches |

| 2.4 * 150mm / 0.09 * 5.91 inches |

2.4 * 175mm / 0.09 * 6.89 inches |

| 3.2 * 150mm / 0.13 * 5.91 inches |

3.2 * 175mm / 0.13 * 6.89 inches |

Weight: about 50-280 grams / 1.8-9.9 ounces

COMPARISON TABLE OF TUNGSTEN ELECTRODE DIAMETER AND CURRENT

|

DIAMETER

|

DC- (A)

|

DC+ (A)

|

AC

|

|

1.0mm

|

10-75A

|

1-10A

|

15-70A

|

|

1.6mm

|

60-150A

|

10-20A

|

60-125A

|

|

2.0mm

|

100-200A

|

15-25A

|

85-160A

|

|

2.4mm

|

170-250A

|

17-30A

|

120-210A

|

|

3.0mm

|

200-300A

|

20-25A

|

140-230A

|

|

3.2mm

|

225-330A

|

30-35A

|

150-250A

|

|

4.0mm

|

350-480A

|

35-50A

|

240-350A

|

|

5.0mm

|

500-675A

|

50-70A

|

330-460A

|

| Please select the corresponding tungsten electrode specifications according to your current use |

Application:

Pure tungsten electrode does not add any rare earth oxides and has the smallest electron emission ability, so it is only suitable for welding under AC heavy load conditions, such as welding of aluminum and aluminum-magnesium alloys.

Main Characters:

|

Model

|

Added

Impurity

|

Impurity

quantity%

|

Other

Impurities%

|

Tungsten%

|

Electric

discharged

power

|

Color

sign

|

|

WP

|

-

|

-

|

<0.20

|

The rest

|

4.5

|

Green

|

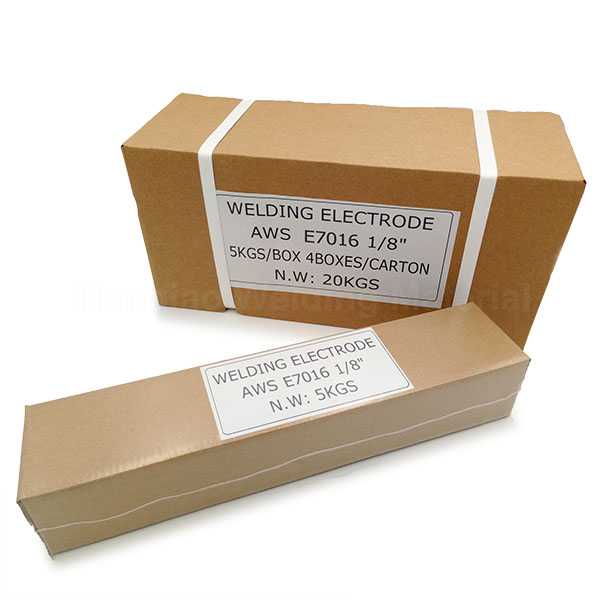

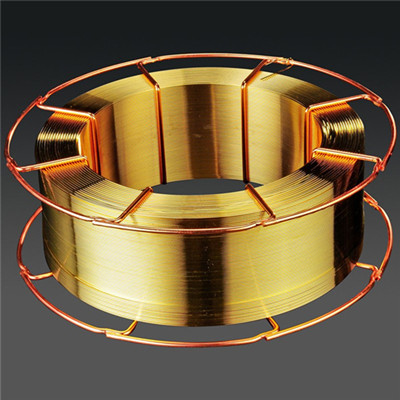

electrode,electrodes,welding,welding electrode,welding electrodes,welding rod,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding sticks,china welding rods,stick electrode,welding consumables,welding consumable,China electrode,welding electrodes China,carbon steel welding electrode,carbon steel welding electrodes,welding electrode factory,Chinese factory welding electrode,China welding electrode,China welding rod,welding rod price,welding supplies,wholesale welding supplies,global welding supplies,arc welding supplies,welding material supply,arc welding,steel welding,easy arc welding electrode,arc welding electrode,arc welding electrodes,vertical welding electrode,price of welding electrodes,cheap welding electrode,acid welding electrodes,alkaline welding electrode,cellulosic welding electrode,china welding electrodes,factory electrode,small size welding electrodes,welding materials,welding material,welding rod material,welding electrode holder,nickel welding rod,j38.12 e6013,welding rods e7018-1,welding stick electrode,welding rod 6010,welding electrode e6010,welding rod e7018,welding electrode e6011 ,welding rods e7018,welding electrodes 7018,welding electrodes e7018,welding rod 6013,welding rods 6013,welding electrode 6013,welding electrode e6013,6010 welding rod,6010 welding electrode,6011 welding rods,6011 welding electrodes,6013 welding rod,6013 welding rods,6013 welding electrode,6013 welding electrodes,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrodes,welding electrode e7016 ,e6010 welding rod,e6011 welding rod,e6013 welding rod,e7018 welding rod,e6013 welding electrode,e6013 welding electrodes,e7018 welding electrode,e7018 welding electrodes,J421 welding electrode,J422 welding electrodes,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7018,best welding electrode,best welding electrode J421,stainless steel welding electrode,stainless steel welding rod,stainless steel electrode,SS welding electrode,welding rods e307,welding electrode e312,309l welding rod,316 welding electrode,e316l 16 welding electrodes,cast iron welding electrode,aws Eni-Ci,aws Enife-Ci,surfacing welding,hard facing welding rod,hard surfacing welding,hardfacing welding, welding, welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding, welding,flux powder,welding flux,welding powder,welding electrode flux material ,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrodes,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,electric are welding,electric arc welding,arc welding rods,carbon arc welding,e6013 welding rod uses,types of welding electrodes,flux core welding,types of electrodes in welding,welding supply,welding metal,metal welding,shielded metal arc welding,aluminum welding,welding aluminum with mig,aluminum mig welding,pipe welding,welding types,types of welding rod,all types of welding,welding rod types,6013 welding rod amperage,welding rods electrodes,welding electrode specification ,welding electrode classification ,welding electrode aluminium ,welding electrode diameter ,mild steel welding,stainless steel welding,e6011 welding rod uses,welding rods sizes,welding rods price,welding electrodes size,aws e6013,aws e7018,aws er70s-6,stainless steel welding wire,stainless steel mig welding wire,tig welding wire,low temp welding rod,6011 welding rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,welding products,welding tech,welding factory

Previous: ODM Supplier China International Standard Stainless Welding MIG Flux Cored Welding Wire E71t-1

Next: WZ8 Zirconium Tungsten Electrode for TIG Welding